#Research & Development

DigiCafé – Espresso meets Industry 4.0

All components are networked via the Message Queuing Telemetry Transport (MQTT) protocol, enabling process data such as temperature, time, flow rate, weight and energy consumption to be digitally recorded, analysed and visualised. The system is supplemented by a digital simulation model of the machine.

The coffee machine clearly demonstrates how existing systems can be digitised through targeted retrofitting – without expensive new purchases. This allows processes to be analysed, energy consumption and quality to be evaluated, and optimised through targeted parameter adjustment.

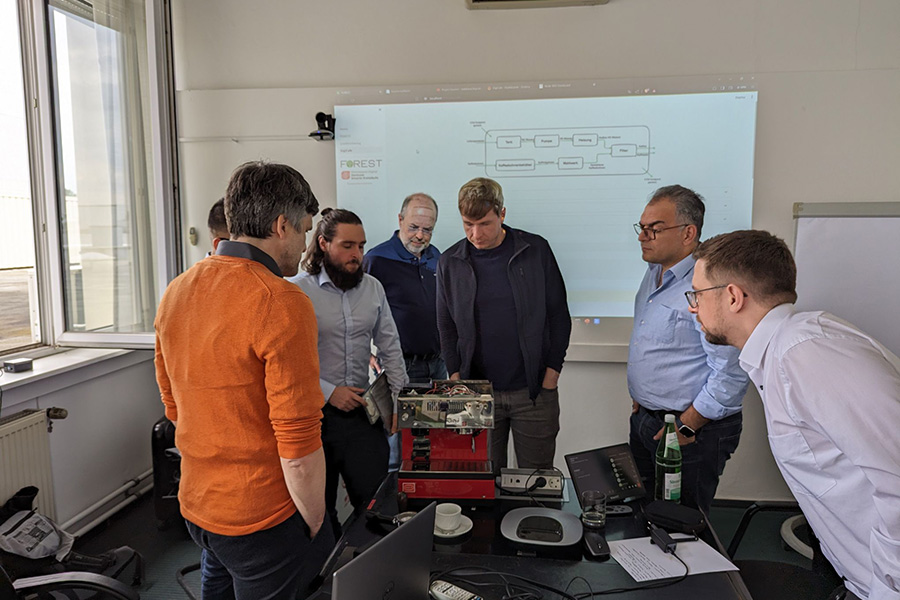

The entire development process, from technical retrofitting and data connection to digital modelling, was carried out at ITA Institut für Textiltechnik of RWTH Aachen University. The demonstrator has been used at trade fairs and training courses since 2023 to provide a low-threshold introduction to the Internet of Things (IoT), retrofitting and digital process optimisation. It has been continuously developed since then.

The project was implemented as part of the publicly funded Mittelstand-Digital Zentrum Smarte Kreisläufe (SME Digital Centre for Smart Cycles) and is a prime example of practical digitalisation in an SME context. It can be viewed or brought along at any time – please contact Rosario Othen ( rosario.othen@ita.rwth-aachen.de )