#Research & Development

Hohenstein: 80 Years of Setting Standards

Testing and research laboratory ensures safe and more sustainable products worldwide

Pioneers of Textile Safety

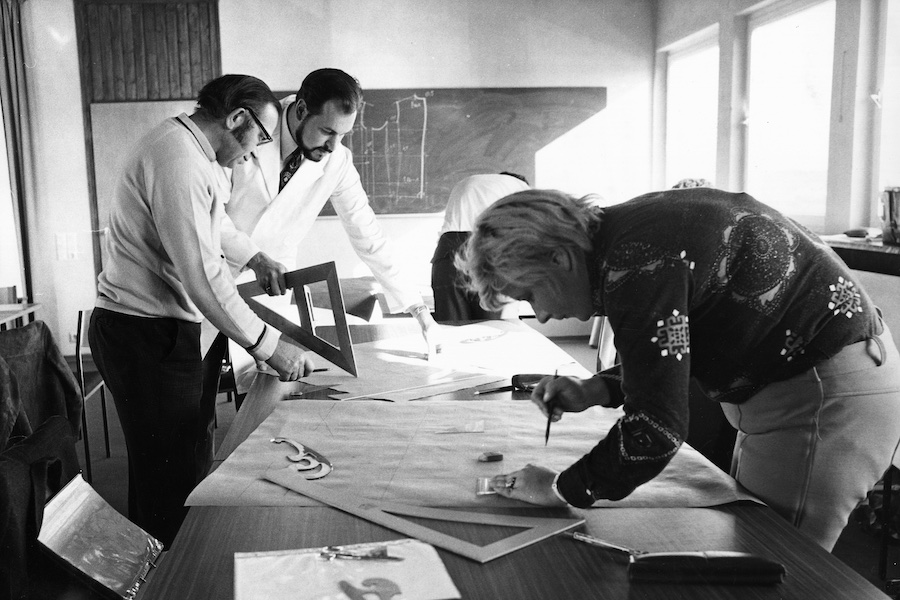

Hohenstein was founded in 1946 by Otto Mecheels as a research institute for the textile industry and clothing physiology. From the very beginning, the institute combined scientific research with practical application – an approach that continues to define Hohenstein to this day. Early series measurements for body-size charts laid the foundation for the company’s fit expertise and knowledge transfer played a central role from the start, with research, teaching and testing closely interlinked.

In 1962, Jürgen Mecheels took over the management of the institute. During this period, Hohenstein developed new testing methods and became a central hub connecting textiles, microbiology and consumer protection. A major milestone followed in 1992, when Hohenstein, as a founding member of OEKO-TEX®, helped set important benchmarks for safe and more sustainable textiles.

A Period of Dynamic Change

In 1995, under the leadership of Stefan Mecheels, Hohenstein began its consistent international expansion. New laboratories in Hong Kong, India and Bangladesh extended the global network. At the same time, the Hohenstein Academy evolved into an established provider of professional training and education. Today, the company is managed by two external CEOs, supported by a family advisory board. “In 2025, I deliberately entrusted the management of Hohenstein to people whom my family and I deeply trust,” explains Stefan Mecheels. “Even after 80 years, Hohenstein therefore stands for continuity and responsibility – while at the same time embracing fresh momentum and innovation.”

Diversification for Global Success

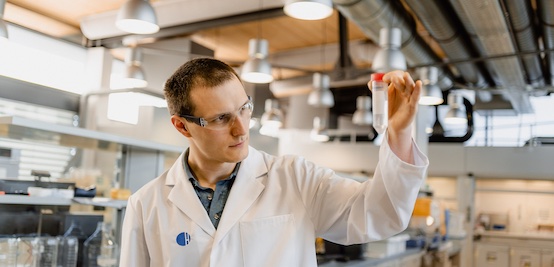

Under the leadership of Stefan Droste and Timo Hammer, Hohenstein has strategically expanded its portfolio. Alongside textiles, hardlines and medical devices have become key areas of Hohenstein’s testing expertise. In the modern hardlines laboratories, products such as toys, frying pans, and suitcases are tested. The medical devices division is certified according to recognized GLP standards (Good Laboratory Practice) and underscores Hohenstein’s high quality standards.

The portfolio is further complemented by the Apparel Fit Solutions division, which combines innovative 3D technologies with classical expertise to provide customers with optimal fit and perfect cut. In this way, Hohenstein individually supports its clients from testing through certification to market launch – ensuring safe and reliable products worldwide. “For us, excellence means more than simply meeting standards,” says CEO Stefan Droste. “Our testing and certifications build trust – both among our partners and among the people who use the products.” Accordingly, Hohenstein is actively involved in the OEKO-TEX® Association, standardization committees, the development of new testing methods, and the research of sustainable processes.

Setting New Standards

With a global network in more than 50 countries, state-of-the-art laboratories and short turnaround times, Hohenstein will continue to support companies in bringing products to market reliably, more sustainably and safely. Today, more than 1,500 employees work for the testing and research service provider worldwide. “We are continuously evolving – both technologically and as an organization,” emphasizes CEO Timo Hammer. “Care and integrity form the foundation of our daily work. Our success in the medical devices and hardlines sectors demonstrates the value of our interdisciplinary expertise. Our ambition goes beyond technical excellence: we take responsibility – for tested products, for their users and for a future that concerns us all.”

Hohenstein at a Glance

- 1,500+ employees worldwide

- Accredited testing laboratories in 6 countries

- 1992 Co-founder of OEKO-TEX®

- Founded in 1946

- 650+ employees at headquarters in Germany

- Representative offices in 50+ countries

- 10.000+ OEKO-TEX® MADE IN GREEN Labels

- 80 years of expertise