#Research & Development

IPF at DESY: Investigations of structure formation in polymers

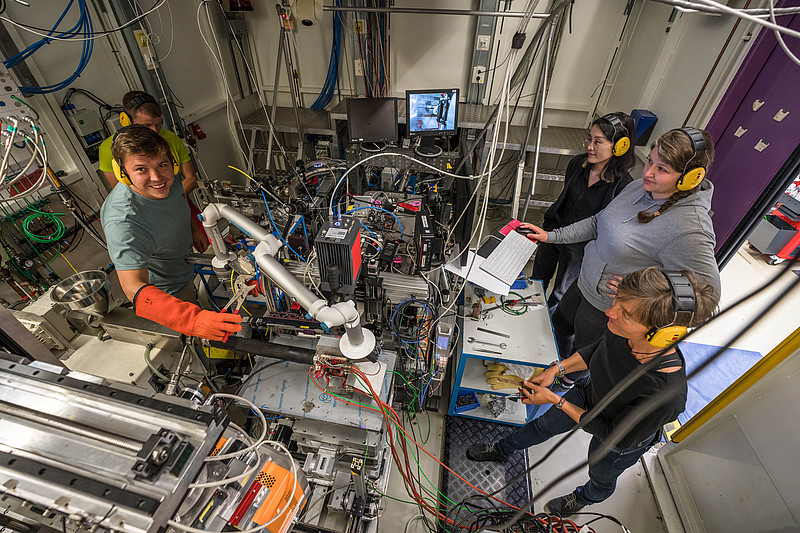

For the first time, the FlowCell device developed at the IPF was used in combination with a conventional single-screw extruder at the MiNaXS beamline P03 to investigate the crystallization kinetics during the solidification of processed iPP, PA6 and PLA melts. The experiments could only be performed remotely, consequently, the FlowCell and extruder control had to be fully integrated into the instrumentation of the beamline.

The conducted experiments are part of the IPF-DESY Long-Term Project (LTP, no. II-20220003) to develop an experimental setup for in situ investigations of (micro)structure formation in polymers (transcrystalline structures, flow-induced crystallization, phase separation) under defined process conditions that are typical and relevant for common melt processing technologies such as extrusion or injection molding.

The IPF scientists would like to thank Matthias Schwartzkopf and Sarathlal Koyiloth Vayalil for the excellent support at the beamline and the team of IPF Research Technology (Forschungstechnik) for the technical implementation of the research ideas.