#Research & Development

PhD student receives Peter Dornier Foundation Prize for new findings on reducing noise and surface heat in aircraft and space capsules

When an object moves through the air, a physical phenomenon called boundary layer flow occurs close to its surface. It appears on the wings of aircraft as well as on the outer walls of space capsules on re-entry into the Earth's atmosphere; it also forms on the surface of wind turbine blades, cars and trains. "The boundary layer flow is only a thin area, but it is crucial for many flow phenomena," explains Lara De Broeck. The young scientist at the Chair of Fluid Dynamics at TU Darmstadt studies such flow phenomena in boundary layer flow. Her research also deals with the question of how the surface properties of aircraft and space capsules affect boundary layer flow.

For her work on the influence of surface structures on boundary layer flow and how these can be used specifically to reduce noise and friction in aircraft and spacecraft, PhD student De Broeck received the Peter Dornier Foundation Prize 2023 at the end of October. The jury of the prize, which is endowed with 5,000 euros, thus honoured the 31-year-old's Master's thesis entitled "Noise suppression in boundary layer flows through optimised acoustic wall impedance". During her acceptance speech at the technical centre of the Lindau DORNIER in front of around 100 invited guests, award winner De Broeck said: "I am truly honoured and very pleased that the jury of the Peter Dornier Foundation Prize has awarded an analytical fundamental work like mine."

Analytical preparatory work for aerospace companies?

In her Master's thesis, De Broeck was able to derive "for the first time" an analytical equation for the mentioned problem description, explains her doctoral supervisor Prof. Dr.-Ing. Martin Oberlack from TU Darmstadt. According to De Broeck, her analytical calculations could provide fundamental insights into how aerospace companies in the future can design, for example, the inner walls of aircraft turbines or the outer walls of space shuttles in such a way that acoustic and thermal disturbances in the boundary layer flow are even better damped. "This could reduce the noise and frictional resistance of aircraft, space capsules and other high-speed vehicles" says De Broeck.

Noise protection was an important topic for founder Peter Dornier

?In her laudatory speech, the Chairwoman of the Peter Dornier Foundation, Maja Dornier, said that De Broeck's Master's thesis deals with a topic that was very close to the heart of the foundation’s founder, Peter Dornier (1917-2002): "Pleasant sounds were important to him throughout his life - this included classical music in his study as well as questions of noise protection in the construction of new aircraft and weaving machines." For the mechanical engineer and aircraft designer, who founded the machine and plant manufacturer Lindauer DORNIER in 1950 and led it successfully for many decades, questions of acoustic quality in the design of new aircraft, machines and plants were of great importance. As early as the 1950s, when the family-owned company DORNIER had just entered the weaving machine manufacturing business, Peter Dornier designed the "encapsulated" weaving machine. Because at that time it could be as noisy in a weaving mill as on the tarmac of an airport, he wanted to protect the operating personnel from the machine noise with the idea of an encapsulated – i.e. housed – weaving machine. DORNIER, today Germany's largest weaving machine manufacturer, later realised the encapsulated weaving machine together with a world-leading weaving mill in Italy.

Award-winning work could improve heat protection of space capsules?

The findings from De Broeck's Master's thesis could also help in the future to reduce the frictional resistance on the surface of space capsules during re-entry into the atmosphere and thus reduce surface heating. In spaceflight, re-entry into the Earth's atmosphere is considered an extremely critical phase. Here, the capsules reach speeds of up to 30,000 kilometres per hour. The outside temperatures rise to over 2500 degrees Celsius. By comparison: lava is 700 to 1200 degrees Celsius hot.

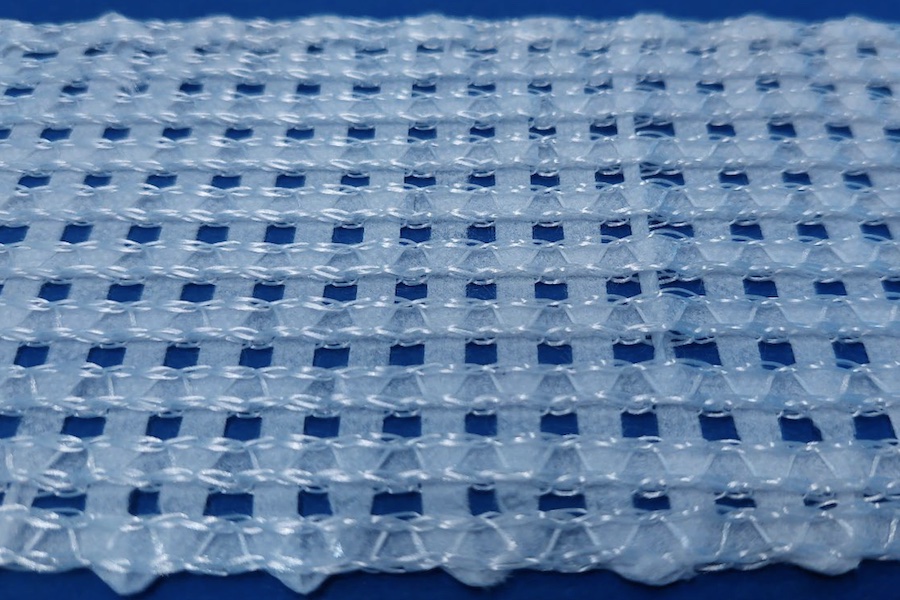

To withstand these temperatures, the space capsules are equipped with special heat protection tiles. These are often made of glass fibre composites, which are also produced on DORNIER air-jet and rapier weaving machines. "If it is possible to adapt the surface structures of space capsules in such a way that they generate less friction and thus less surface heating, material could be saved on the heat protection tiles," De Broeck explained. How this can be achieved motivated her to write her Master's thesis, De Broeck said, because such a weight saving could increase the payload of space capsules. Interesting side note: The parachutes on which space capsules glide safely to earth are also woven on DORNIER weaving machines.

Famous equations from mathematics as basis for Master's thesis

?For the calculations in her Master's thesis, which was awarded the Peter Dornier Foundation Prize, De Broeck also uses simplifications of the famous Navier-Stokes equations. These equations, named after the mathematicians Claude Louis Navier and George Stokes, serve to describe flows and are among the most important equations in fluid mechanics. They are used in calculations for the aerodynamics of aircraft as well as for weather and climate forecasts. Moreover, they are among the so-called "millennium problems" – seven unsolved mathematical puzzles for whose solution the Clay Mathematics Institute offered a prize of one million dollars each in the year 2000.

De Broeck, who committed herself privately to helping refugees and schoolchildren during her studies, also attracted interest with her work at the renowned Stanford University. The young scientist was invited there for a research stay co-financed by NASA. According to De Broeck, participants were pleased to be able to complement their own research work with De Broeck's analytical calculations. "It was great to meet leading experts in the field of fluid dynamics and turbulence research whose books you normally only read in your studies," reported De Broeck in a relaxed atmosphere after the award ceremony.

The Peter Dornier Foundation Prize

The idea of the Peter Dornier Foundation Prize goes back to Peter Dornier (1917-2002), founder of Lindauer DORNIER GmbH. Since 2021, the prize has been awarded annually for outstanding scientific work by young people in the fields of textile technology, film stretching technology and composites as well as aviation. Funding medical research is just as much a part of the foundation's purpose as supporting hospices for a self-determined and dignified life until the end.