#Research & Development

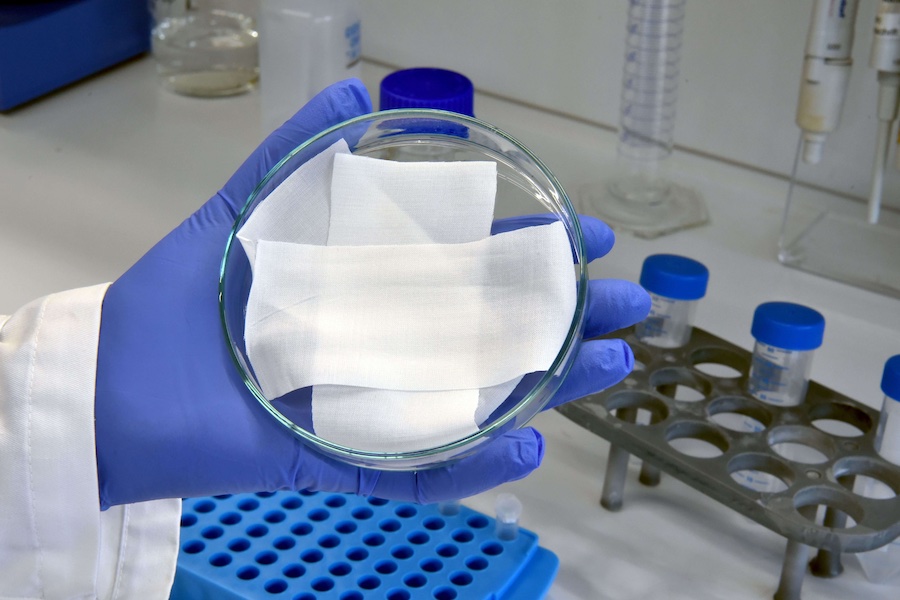

WhiteCycle - DITF are part of an international consortium for plastics recycling

Under the leadership of Michelin Group France, the consortium 'WhiteCycle' was constituted at the beginning of July 2022. The aim of the European initiative is to establish an economic cycle to process inhomogeneous textile waste from different materials and to manufacture new, high-quality products from it. This project is intended to help achieve the targets set by the European Union for reducing CO2 emissions by 2030.

Complex, textile-containing PET waste such as tires, tubes or multilayer composite textiles from the clothing sector have so far been difficult or impossible to recycle. Under the WhiteCycle network, several projects and research approaches will be brought together to address the problem and provide new solutions.

The DITF will adapt an existing PET synthesis process to novel recycled monomers. The fundamental problem to be overcome is the impurities in the starting material due to its inhomogeneous composition. Together with the project partner Kordsa Teknik Textil A.S. (Turkey), the DITF are developing new synthesis concepts. Their aim is to eliminate possible disadvantages caused by residual contamination of the monomers. This is because, despite purification of the monomers prior to further processing, not all impurities can be removed. The approaches taken are demanding. For example, the type and quantity of additives used must be specifically adapted. These include catalysts, processing aids, nucleating and coupling agents, and chain extenders. In this way, it is possible to avoid the negative effects of unknown impurities. This improves the material properties of the recycled plastics, as they are thermally stabilized in the long term, which in turn results in improved mechanical and rheological properties. The modified process should enable recycled PET (r-PET) to have the same properties as commercial PET.

The consortium partners are pursuing other approaches to produce an improved recycling rate and higher-quality r-PET products: optimized sorting technologies for the sorting of waste are part of this, as is enzyme-based treatment of plastics to break them down into monomers in a sustainable way. Ultimately, the high-quality manufacture of new products from the recycled plastics will also help to close the raw material cycle.