#Research & Development

European cooperation for the production of oxide ceramic fibers

Saint-Gobain is a French group listed on the stock exchange, that designs, manufactures and distributes materials and solutions for the construction and other industrial application markets. The companies united under its umbrella employ approximately 167,000 people with annual sales of over 38 billion euros. Saint-Gobain is represented in 72 countries worldwide. Saint-Gobain is, among other things, a manufacturer of innovative ceramic materials and products in its Ceramics Business Unit.

The cooperation aims at jointly creating, ultimately, the production of metal oxide ceramic fibers in Europe.

At DITF, research and development in the field of ceramic fibers has been carried out continuously since 1990, so that extensive and well-founded know-how exists. The results and status of the research have been presented in a number of scientific publications and at various international conferences, which drew the attention of several companies to the research results and expertise of the DITF. After an extensive evaluation and negotiations with several potential partners, Saint-Gobain emerged as the ideal collaboration partner due to the complementary expertise of the two partners.

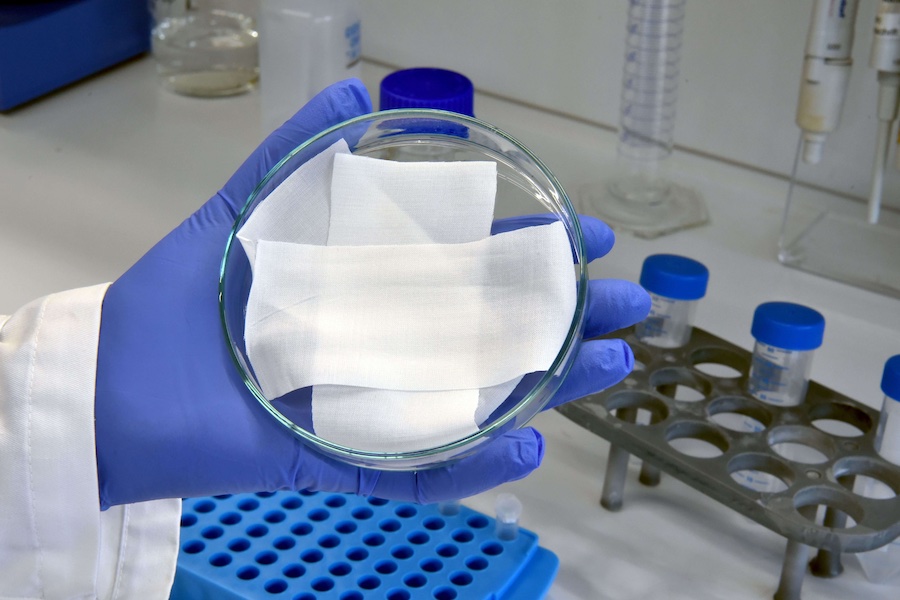

Metal oxide ceramic fibers are an essential component of fiber-reinforced ceramic materials (CMC: Ceramic Matrix Composites), which are increasingly important for a wide range of high-temperature applications. Fiber reinforcement produces a damage-tolerant ceramic material that is no longer brittle and is superior to monolithic ceramics, making it highly desirable from a technical and commercial point of view. Potential applications include components in industrial furnaces, charge carriers for temperature treatment and, in the high-tech sector, components in high efficiency stationary gas turbines, lower fuel consumption aircraft gas turbines and in space applications. A significant increase in the industrial use of CMCs is forecast for the coming years, and with it, a growing demand for ceramic fibers.