#Research & Development

Cellulose fibers against climate change

Such so-called 'direct air capture technologies', are already being tested from various approaches on a research scale or in pilot plants. In one of these processes, special filters are used to remove CO2 from the atmosphere. As part of a research project, the DITF are developing textile materials for separating CO2 from the air. CO2 can be fixed in this way over the long term and thus permanently removed from the climate cycle. Or it can be used as a raw material for the production of CO2-neutral hydrocarbons.

While several companies are already competing internationally to find the best technology for extracting CO2 from the air in large quantities and profitably, the economics still stand in the way of the really big breakthrough: The small proportion of CO2 in the atmosphere (0.04%) requires enormous amounts of air to be pumped through the filters in order to filter out a significant proportion of CO2. Separating the absorbed carbon dioxide from the filters in turn requires larger amounts of thermal energy. Economic operation is not possible under current conditions. In the further development of CO2 separation from air, it will therefore be necessary to turn several screws to increase the technological efficiency of the process while minimizing energy consumption.

Self-sufficient air filter for CO2 separation

A joint research project of the Center for Solar Energy and Hydrogen Research Baden-Württemberg, DITF Denkendorf, the Institute for Energy and Environmental Research Heidelberg and Mercedes-Benz AG Sindelfingen aims to realize an improved, highly efficient CO2 capture from air using tissue-fixed amines. The process is to be implemented in a demonstrator that can be operated autonomously: resource consumption is to be based purely on renewable electricity and waste heat, covered by solar energy or heat pumps. The special design of the air filter will enable continuous operation of the plant, unlike already established processes. This improves upscalability to industrial scales.

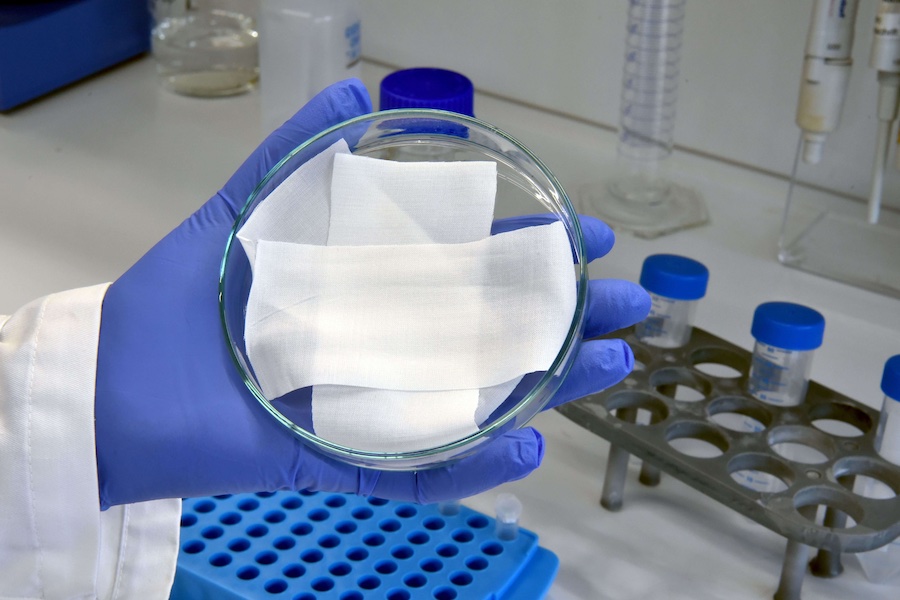

Within this four-year joint research project, the DITF is contributing its many years of expertise in the development of cellulose-based fiber materials. They will be used as filter media in the demonstrator. Based on the results of a previous research project, in which a screening of possible processes for CO2 removal from the air and the sorbent materials used for this purpose had already been carried out, cellulose-based fiber materials were chosen for the current research project.

Under the direction of Dr. Frank Hermanutz, the fibers for the filters are spun out in the Biopolymer Materials Competence Center and chemically modified so that they couple amines to their surface. New spinning processes are being developed and optimized for this purpose in the DITF pilot plants. The amines ensure the temporary binding of the CO2 to the filter material. The advantage of using fiber-based cellulose lies in the open, air-permeable structure of fiber-based materials. Not only do they allow a high air throughput, but they also have a large specific surface area, which is advantageous for binding the largest possible volumes of CO2. The aim of the chemical modification of cellulose will be to optimize both the fiber itself and the binding of the amines in such a way that the adsorption capacity for CO2 is exploited to the full.

A completely new process engineering concept is pursued in the design of the filter: A static filter is not used, as is usually the case, which has to be baked out after the amino groups have been completely loaded with CO2. Instead, the filtration process is integrated into a continuously operating process that permits continuous and energy-saving operation. If the system is connected to existing air streams such as building air conditioning systems or exhaust air, there is no need to use energy-intensive fans.

The filter is designed as a special belt apparatus in which the cellulose fibers are processed into endless belts in the form of nonwovens. These belts, like a conveyor belt, run on roller conveyors through the incoming air stream and bind the CO2 there. The belts are then heated in three temperature zones in a spatially separated desorption area. There, water and CO2 separate from the amino groups.

The continuous process made possible by the circulating nonwoven belts allows cost-saving and low-maintenance process control. In addition to the extraction of CO2, the separate extraction of water will also represent a synergetic effect of high value: Since the plant is already designed for energy self-sufficient operation, it is in principle possible to operate it in areas with poor infrastructure and water scarcity. Water harvesting can then represent a not inconsiderable added value. The design as a belt unit makes it easier to scale up the process to very high performance classes, since this requires above all an easy-to-implement increase in belt length.