#Raw Materials

Better Cotton Initiative opens enrollment in the US with promising opportunities for producers

Those interested in working with BCI can fill a brief Producer & Program Partner Interest Survey or learn more about the US Program below.

BCI‘s farm-level standard is built on regenerative environmental and social principles including farm and labor management, soil health, biodiversity, water management, and crop protection. The organization is funded primarily by its supply chain membership through annual fees and additional program investment based on BCI volumes purchased. Most BCI-Certified Producers pay no certification fees.

Working with BCI increases market entry opportunities with exposure to a global network of over 300 retailers and brands who source BCI cotton, along with access to resources and industry recognition. BCI certification further enables producers to market their fiber as BCI Cotton globally. By implementing practices which meet BCI’s criteria – practices many already employ on their farms – producers also stand to benefit from cost savings and farm resilience while contributing to positive environmental impacts.

In 2025, BCI released its 10-Year US Impact Report showcasing regional data insights, production statistics and special features on the US Program’s vast network of collaborators.

Current opportunities for US Producers

Producers working with BCI are at the heart of its mission. In the US, the program is now offering additional assistance beyond certification activities, at no financial cost to the producer.

Conservation planning: BCI is now working with individual BCI-Certified Producers to develop individualized conservation plans. These plans can help cotton producers assess soil health, IPM tactics, and other resources concerns and access USDA funding, including the new NRCS regenerative agriculture program. In addition, the plans help BCI producers comply with its standard and navigate additional regulations like new EPA pesticide rules.Learn about producer Terry Fuller and his experience with BCI Conservation Planning.

On-farm innovation projects: BCI’s US Program offers limited funding for producers to field test innovative, regenerative practices on their farms. The program helps support producers like fifth-generation North Carolina farmer Zeb Winslow who are testing new approaches on their farms to ensure profitable and resilient systems.

Carbon programs by Indigo Ag: BCI-Certified Producers may also be eligible to participate in Indigo Ag’s Carbon program, which is inclusive of multiple crops, recognizes practices many are already implementing, and returns 75% of the carbon credit purchase price to the producer. BCI is also working with Indigo Ag on its Source program to develop a way for Retailer and Brand Members to purchase carbon reductions and removals in their supply chains.

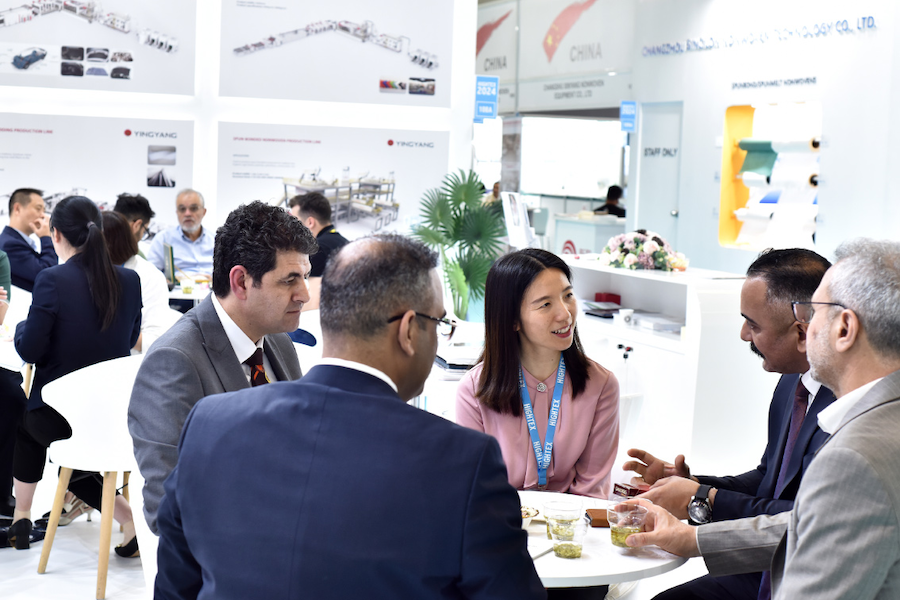

Building connections across the globe: BCI works to connect cotton producers with advocates, buyers and fellow producers to forge a strong network. BCI-Certified Producers and Program Partners regularly meet both virtually and in person to share challenges and new ideas.

US producers are invited to fill out this brief interest survey with their basic farm info, or reach out to us.team@bettercotton.org to learn more about any of these programs.

https://survey.alchemer.eu/s3/90892812/Interest-Survey