#Raw Materials

Study reveals that cotton microfibers biodegrade faster than tissue paper microfibers in wastewater treatment, frresh water and saltwater environments

The researchers showed that cellulosic microfibers from flushable wipes, tissue paper, and cotton fibers generated from bleached cotton jersey knit fabric biodegraded extensively across all tested conditions.

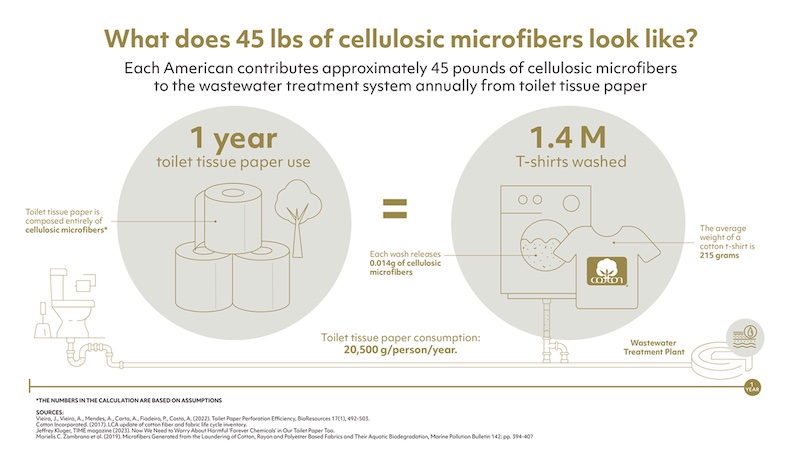

“Since toilet tissue microfibers enter the wastewater treatment system at a rate of 45 pounds per year per person in the United States, they are one of the most significant contributors to cellulosic microfibers. The annual microfiber emissions from toilet paper use in the United States equals the microfiber shedding from washing 1.4 million T-shirts.[1]” said Jesse Daystar, Ph.D., vice president and chief sustainability officer at Cotton Incorporated. “Our research confirms cotton microfibers biodegrade equal to or faster than toilet tissue microfibers in wastewater treatment, fresh water and saltwater environments, demonstrating society’s and nature’s ability to manage them.”

The study also found that the presence of polypropylene in blended nonwoven wipes did not hinder the biodegradation of the cellulose component. This suggests that even when combined in a single product, the cellulosic component can still degrade independently, while the polypropylene remains undegraded.

“These results reaffirm that fibers found in these cellulosic and cotton-based products can biodegrade easily in various environments,” added Mary Ankeny, vice president of product development and implementation operations at Cotton Incorporated. “Our research highlights the importance of choosing natural fibers over synthetic alternatives to reduce the accumulation of non-biodegradable waste in our environment in order to promote a more sustainable future.”

Methodology

This research studied the biodegradation of cotton microfibers, commercially available flushable wipes, polypropylene-based nonwoven wipes with a cellulose component, and toilet tissue. The biodegradation was tested in wastewater treatment plant solids, seawater, and lake water using standard methods in an ECHO respirometer. The experiments continued until carbon dioxide (CO2) emissions plateaued, and the final extent of biodegradation was calculated based on the theoretical CO2 production derived from elemental analysis.

[1] Calculated based on these assumptions: 1. Tissue paper is composed entirely of microfibers 2. The average weight of a cotton t-shirt is 215 grams 3. The average toilet paper consumption in the US is 20,500 g/person/year. 4. On average, each t-shirt wash releases 0.014 g of microfibers per t-shirt.

Sources:

Vieira, J., Vieira, A., Mendes, A., Carta, A., Fiadeiro, P., Costa, A. (2022). Toilet Paper Perforation Efficiency, BioResources 17(1), 492-503.

Cotton Incorporated. (2017). LCA update of cotton fiber and fabric life cycle inventory.

Jeffrey Kluger, TIME magazine (2023). Now We Need to Worry About Harmful ‘Forever Chemicals’ in Our Toilet Paper Too.

Marielis C. Zambrano et al. (2019). Microfibers Generated from the Laundering of Cotton, Rayon and Polyester Based Fabrics and Their Aquatic Biodegradation, Marine Pollution Bulletin 142: pp. 394-407