#Nonwovens / Technical Textiles

A new, sure-fire success is in the starting blocks

Successful launch of the RDJ 6/1 EN, with its high cost:benefit ratio, for the shoe fabric sector

However, there is very little difference in terms of the design potential. Almost 90 % of the jacquard shoe fabrics currently produced can be manufactured on the RDJ 6/1 EN. The configuration of this new machine makes it ideal for producing engineered spacer textiles. Compared to the RDJ 5/1, the RDJ 6/1 EN has one extra guide bar, EN drive and a wellthought- out yarn feed system to the jacquard bars, and offers extended design possibilities, a higher product quality, and easy pattern change. The cost is still competitive.

A high-performance machine for producing shoe fabrics

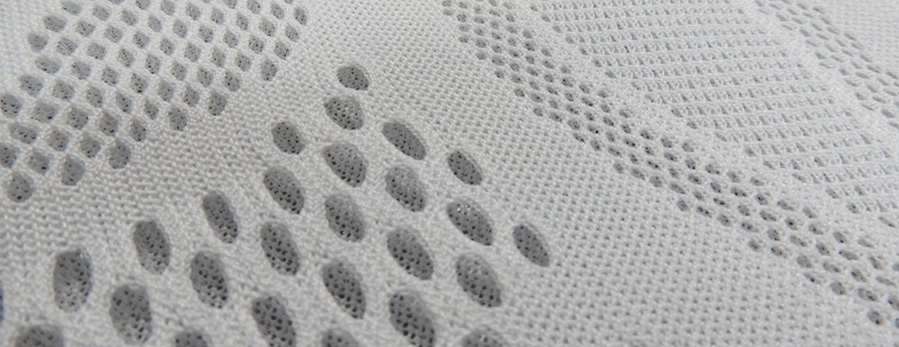

The RDJ 6/1 EN is available in the gauges of E 22 and E 24, and has a working width of 138". The distance between the knock-over comb bars can be adjusted continuously from 2 mm to 8 mm. Customers can now buy a flexible production machine with five guide bars, one split jacquard bar, whose split bars can operate in a counter lapping operating mode, and an EN pattern drive. It can also produce an extensive range of fabrics. Dense structures can be worked, as well as a wide range of patterns with holes, which can be of any size and placed in any location. The result is attractive shoe fabrics with a specific breathability. If the split jacquard bars are moved in a counter lapping operating mode, the contours of the openings are exceptionally clear. In this case, the yarn is fed from two sectional warp beams. T

his facilitates yarn drawing-in and doubles the yarn running times – with a positive effect on the productivity The EN drive makes a further contribution to increasing the efficiency. The seven electronic guide bar drives enable the patterns to be changed very easily and flexibly, and the costs of buying, storing and changing the pattern discs are eliminated. Like all KARL MAYER’s machines, the RDJ 6/1 EN can also be operated very easily. A new feature compared to the RDJ 5/1 is that the machine and knitting elements are equipped with LED lighting as standard. The increased visibility simplifies handling even more, especially when drawing-in the yarns. This new doublebar raschel machine is completely compatible with the RDJ 5/1 and the RD 7/2-12 EN as far as the knitting elements are concerned. This reduces the storage requirements for spare parts.

Successful market launch

The RDJ 6/1 EN was presented to a wide audience for the first time at the in-house show held at KARL MAYER (CHINA) during ShanghaiTex, which took place from 25 to 28 November 2019. The visitors asked many questions about the new machine. Yuji Yamamoto, the Product Manager at NIPPON MAYER, is preparing to have many discussions on various projects in the next few months. Mass production was scheduled to start in September 2019, and the first machines have already been sold.