#ITMA Asia + CITME Singapore 2025

ANDRITZ sets focus on textile recycling and durable nonwoven production technologies at ITMA Asia 2025

ENTERING A NEW MARKET: COMPLETE MMCF PRODUCTION SOLUTIONS FOR LYOCELL

At ITMA Asia, ANDRITZ introduces its competences in production plants for man-made cellulosic fibers (MMCF), namely lyocell – a rapidly growing market driven by demand for sustainable materials. The solutions cover the full scope, from engineering to specialized equipment like flash dryers and pulp preparation systems. With decades of expertise in pulp and paper, ANDRITZ also provides audits and upgrades for existing plants. The lyocell process stands out for its environmental benefits and high-quality output, making it a key technology for the future of textiles and nonwovens.

CIRCULARITY: TEXTILE SORTING AND RECYCLING SOLUTIONS

ANDRITZ has always been a pioneer in providing industrially and economically viable solutions that bring the circular economy to the world of textile fibers. Thus, ANDRITZ is not only a reliable supplier but also a knowledge provider. The company offers everything from automated textile sorting and textile fiber preparation to mechanical and chemical recycling and combined processes.

A particular focus is placed on ANDRITZ's automated textile sorting process, as this represents the missing link in the true circular economy for textiles. The unique process has been developed through a collaboration between Nouvelles Fibres Textiles, Pellenc ST, and ANDRITZ. The system sorts garments by composition and color, removes hard parts like buttons and zippers, and prepares materials for further processing. It enables efficient recycling of post-consumer and post-industrial textile waste into fibers for spinning, nonwovens, and composites. The implementation of automated sorting technologies marks a turning point in the global effort to reduce textile waste. By addressing the core challenges of fiber identification, color sorting, and contamination removal, ANDRITZ is paving the way for truly closed-loop textile recycling.

HIGH-SPEED CROSSLAPPING: NEW X-PRO CROSSLAPPER

ANDRITZ introduces the new X-Pro crosslapper, a groundbreaking innovation in the crosslapping process for needlepunch and spunlace lines. This new machine sets unrivalled standards in speed, productivity, and quality, overcoming traditional limitations. Its unique "X-path" design ensures precise fiber control, eliminating distortion and enabling flawless overlap regardless of web characteristics. The system maximizes throughput and fabric homogeneity while maintaining superior quality. Additionally, it is fully compatible with ANDRITZ’s ProWin profile correction system, enhancing performance and efficiency to unprecedented levels.

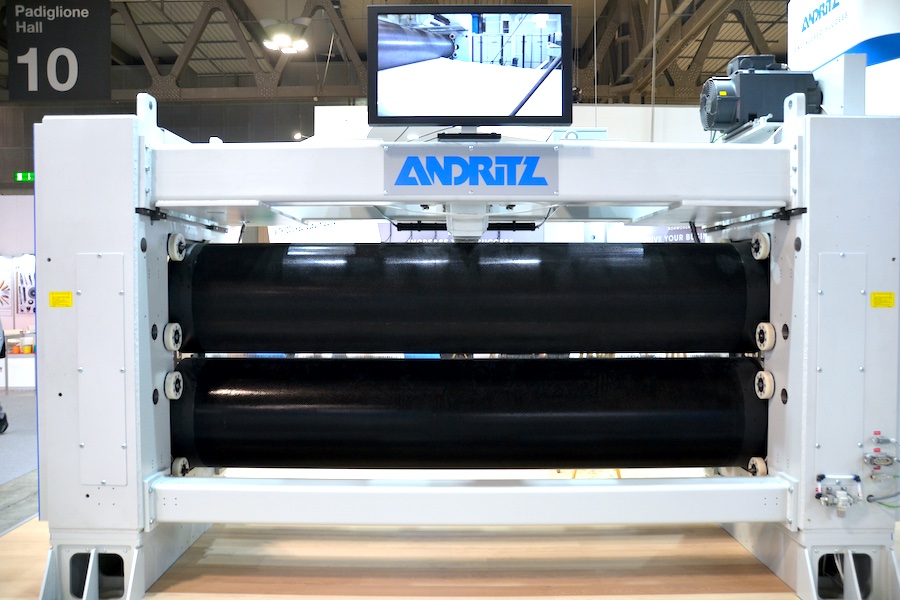

EXPANSION OF NEEDLELOOM PORTFOLIO: NEW NEXLOOM FOR MEDIUM RANGE CAPACITIES

In the area of durable nonwovens, ANDRITZ is pleased to present the new neXloom needleloom, specifically designed to meet the demands of medium-range production capacities across key markets such as synthetic leather, filtration, and automotive applications. Engineered for robust performance and cost efficiency, the neXloom combines the renowned ANDRITZ quality with features that reduce operational and maintenance costs. The machine supports a random needle pattern for enhanced product characteristics and offers optional systems including automatic greasing and cooling, further improving reliability and ease of use.

With a speed range of 850 to 1200 rpm and a stroke range from 25 to 60mm, the neXloom represents a strategic addition to the ANDRITZ portfolio, reinforcing its commitment to innovation and customer-focused solutions in the nonwovens industry.

ANDRITZ teXscan

Premiere at ITMA Asia 2025: ANDRITZ teXscan for predictive textile analysis to determine whether the material is suitable for re-spinning or nonwoven further processing. this new technology raises the productivity of textile recycling.

ADVANCED TECHNOLOGIES FOR NATURAL FIBERS

ANDRITZ highlights its technologies for processing bast fibers, which are gaining importance across industries such as automotive, insulation, geotextiles, construction, and textiles. Known for their low environmental impact and local sourcing potential, bast fibers support circular and zero-waste production models. One major trend is the use of industrial hemp in airlay applications. ANDRITZ offers complete lines combining decortication and refining equipment with neXline airlay systems. These lines are designed for gentle fiber processing, compact layout, and low energy consumption, delivering high-quality fibers suitable for a wide range of applications.

Moreover, ANDRITZ offers a multi-technology, one-stop-shop approach for bio-based textile fiber production. This includes automated sorting, mechanical and chemical recycling, and decortication lines for flax, jute, hemp, and kenaf. By uniquely combining these technologies, ANDRITZ supports the rising demand for sustainable products and empowers companies to achieve long-term economic success in a dynamic market. These solutions open up new opportunities in both spinning and nonwoven markets, enabling the creation of value-driven, innovative products.

LIFE-CYCLE MANAGEMENT: ANDRITZ SYNERGY SERVICE CONTRACTS

Nonwovens and textile producers require state-of-the-art equipment to meet ever-increasing market demands, optimize their energy use, achieve product differentiation for their nonwovens production lines, and/or enhance product quality. ANDRITZ therefore offers the ANDRITZ SYNERGYTM service agreements. They provide efficient and cost-effective solutions to ensure uninterrupted productivity by complementing customers’ in-house capabilities with customized service packages. These agreements are designed to match the life-cycle of the equipment, include regular expert visits, preventive maintenance, retrofits, and upgrades to keep your operations running smoothly and reliably.

The entire ANDRITZ Nonwoven & Textile team is looking forward to welcoming customers and partners at booth D106 in hall 2.