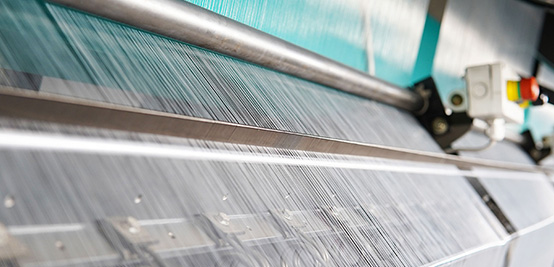

#Knitting & Hosiery

More scope – thanks to a modular design

The LACE.EXPRESS, with its flexible platform concept and width of 134", is now targeting the intimates sector

A special feature of the range is that the models in the series are all compatible with each other. In keeping with the motto, “Create your own production machine”, every machine can be equipped to the technical level of its high-bar neighbours within the platform. Low-bar items can be produced on high-bar machines, without adapting the pattern data. This enables the customer to benefit from maximum flexibility.

Maximum productivity and the ability to adapt to specific requirements

This new machine platform combines the OJ models with different bar configurations in a uniform layout. The range includes the OJ 91/1, OJ 85/1, OJ 65/1, OJ 59/1 and OJ 42/1. All the models are available as B and F versions. The available gauges are E 24 and E 18 and the working width is 134", which are perfect for the intimate apparel sector. This modular platform concept enables the machines to be upgraded into higher bar versions.

For example, an upgrade kit is available for changing an OJ 42/1 into an OJ 91/1 – to expand the range of patterns it can produce. The patterns are also compatible with an increasing number of bars. Customers can change the design from an OJ 42/1 to an OJ 91/1, without having to make any modifications. This unique flexibility is complemented by an exceptionally high production rate. The machines increase output by 100 % for the same investment, compared to their predecessors. Customers are also able to profit from the general benefits of the LACE.EXPRESS series. LEO® reduces the energy consumption of the LACE.EXPRESS machines by 40 %, compared to the previous models. A mobile operator user interface simplifies the setting-up of the string bars and improves the view for monitoring production.

Start of production – with new machines appearing at specific time intervals

As the first model in the new LACE.EXPRESS platform, the OJ 91/1 is available immediately as F and B versions. The first lowbar machines will be available from October onwards.