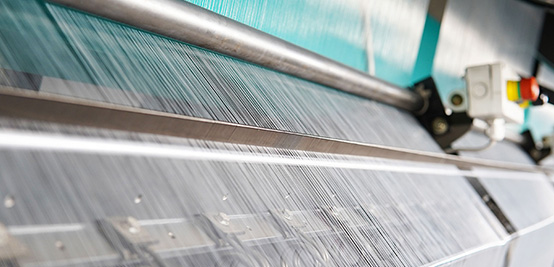

#Weaving

BLUEDYE - for a world in which sustainability is just as stylish as a pair of jeans

As an innovative pioneer in textile machinery and plant engineering, the KARL MAYER GROUP is committed to ecological and social responsibility. The global player is now delighted to receive special recognition for its commitment. On June 11, 2024, the global player received the German Award for Sustainability Projects 2024 in the "Production" category at the Bertelsmann Representative Office in Berlin, where it also took first place out of a total of four award winners.

(© Thomas Ecke / DISQ / ntv / DUP UNTERNEHMER)" alt="The winners of the Award for Sustainability Projects 2024 in the "Production" category

(© Thomas Ecke / DISQ / ntv / DUP UNTERNEHMER)" alt="The winners of the Award for Sustainability Projects 2024 in the "Production" category(© Thomas Ecke / DISQ / ntv / DUP UNTERNEHMER)">

The prestigious prize is awarded by the German Institute for Service Quality, the DUP Entrepreneur Magazine and the news channel ntv. The patron is the former Minister of Justice and Economics Brigitte Zypris, who is also a member of the jury team. The high-caliber decision-making committee examines projects from all sectors of the economy that implement sustainability in an exemplary manner - this year 70 companies from a total of 342 nominations.

The KARL MAYER GROUP impressed the jury with the development of BLUEDYE, a pioneering, high-impact solution for environmentally friendly denim production. The jury praised the project as a good solution that can serve all production improvement goals, including optimizing quality and environmental protection as well as reducing costs. The project is considered to be highly relevant for the sustainable production of jeans.

Arno Gärtner, CEO of the KARL MAYER GROUP, accepted the award and appreciates the recognition.

"As a global company, we are very aware that sustainable products and solutions must never come at the expense of profitability for our customers. Our project has developed a technology for dyeing denim fabrics that reduces consumption of water and chemicals – usually very high – by at least 50% respectively, while at the same time reducing operating costs by up to 20% and meeting the exacting demands that buyers place on the colour quality of denim fabrics and yarns. A more sustainable, trendy pair of jeans that meets the fashion demands of consumers – this is exactly how we aim to exploit new technology to make a significant contribution to sustainable jeans production," says Arno Gärtner.

Less chemicals, water and costs, same product quality

Blue jeans are one of the most popular but at the same time most environmentally problematic items of clothing. Conventional denim dyeing in particular uses vast amounts of water and chemicals. BLUEDYE is a pioneering alternative to the environmentally harmful processes used in today’s denim production. It contributes to no less than four of the United Nations Sustainable Development Goals for companies.

BLUEDYE's nitrogen-based dyeing technology minimizes the significant amounts of water and chemicals traditionally used in the denim dyeing process. The need for the main pollutants hydrosulphite and caustic soda can be reduced by more than 60 % and the amount of water required by at least 50 %. In addition, there is less yarn waste. BLUEDYE thus contributes to sustainable production (goal 12).

Fewer chemicals used also means less water pollution - an advantage that, in combination with the considerable water savings, ensures clean water and thus the fulfillment of goal 6. Fewer pollutants in the production process also result in a healthier, more humane working environment, as called for in Goal 8.

And, as defined in Goal 9, BLUEDYE promotes innovation by introducing state-of-the-art technologies. In 2018, KARL MAYER was granted patents for an advanced denim dyeing technology and developed a marketable system with maximum customer benefit based on its extensive textile machinery expertise.

With BLUEDYE, companies in the denim industry can make their production processes more efficient and environmentally friendly and improve their competitiveness, and this has been proven: The positive effects of BLUEDYE were evaluated by comparative measurements on a pilot plant at a field test customer. Consumption data from a production plant that has been already in operation for some time was used as reference values for comparison

In addition to the environmental performance, the economic efficiency and product quality strike the right note. BLUEDYE can reduce operating costs by up to 20%, while at the same time meeting the high customer requirements for the colour quality of the fabrics and the colour saturation of the yarns in jeans.

To get a closer look at the product’s qualities, register for processing tests at the denim centre of excellence at KARL MAYER ROTAL.