#Industry 4.0 / Digitalization

New innovation center for digital transformation in industry opened

In the technology park near the university, a unique innovation ecosystem has been created after a construction period of only one and a half years, which is designed for the use of digital technologies and, above all, for transfer and collaboration. The hub, funded by the state of Bremen, is primarily intended to enable small and medium-sized industrial companies to undergo the urgently needed digital transformation and serve as a testing ground for innovations and new business models.

Small and medium-sized industrial enterprises (SMEs) in particular are facing major challenges in the face of an increasingly volatile environment. They have to successfully manage their day-to-day business while at the same time developing innovations that will secure business success in the future. Digitalization offers enormous potential for this. The question, however, is how companies are to implement the digital transformation quickly and in a value-creating manner on their own, without sufficient (digital) expertise and with very limited resources. The answer is: not ALONE at all. "In our technologically and organizationally complex world, we can only be successful in the future through collaboration. For us in Germany and Europe in particular, success is increasingly a question of intelligent collaboration," says Lenze CEO Christian Wendler, summarizing the motivation behind the project. He continues in his opening speech: "Our mission at Lenze is to competently accompany SMEs, in particular our medium-sized customers, in their digital transformation and to offer them an ecosystem for this valuable exchange. The Digital Hub Industry offers excellent conditions and an extraordinarily creative environment for this."

The basic idea of the DHI is to create a place for exchange between companies and research fields of the university and colleges. On the one hand, companies like Lenze provide their industrial know-how and contribute their digital challenges and current problems as concrete objects of investigation for research projects. On the other hand, the companies benefit from the research results and can transform them into new digital products, services, or business models.

In her welcoming address, Kristina Vogt, Senator for Economic Affairs, Labor, and Europe, emphasized the importance of the Digital Hub Industry for the state of Bremen: "Medium-sized companies and startups, in particular, are supported and strengthened on their path to digitization through needs-oriented and practical offerings. The Digital Hub Industry thus sustainably increases the attractiveness of our location, it creates new jobs and secures existing ones."

The heart of the hub in the new Neos building with its approx. 16,000 m² of office, laboratory, and event space is an Open Innovation Lab with coworking and maker spaces, diverse laboratory areas, and a large event space. Here, established industrial companies can cooperate specifically with each other, with university scientists or start-ups and "digital" talents. In times of a shortage of skilled workers, the Digital Hub Industry offers another advantage because its proximity to the University of Bremen creates easy access to skilled workers, talents, and innovators.

Testimonials:

Christian Wendler, Chairman of the Executive Board (CEO) of Lenze SE:

"I am convinced that digitalization offers enormous potential for industrial companies. At the same time, I believe that the associated challenges can only be mastered jointly and cooperatively. That's why I'm very pleased about the founding of the Digital Hub Industry in Bremen, which aims to do just that: Unlock the potential of digitalization together. We will become even more attractive for our customers as a partner for comprehensive automation and digitization solutions along the entire value chain."

Christoph Ranze, founder of encoway, responsible for Lenze‘s digital business, and idea provider for the Digital Hub Industry:

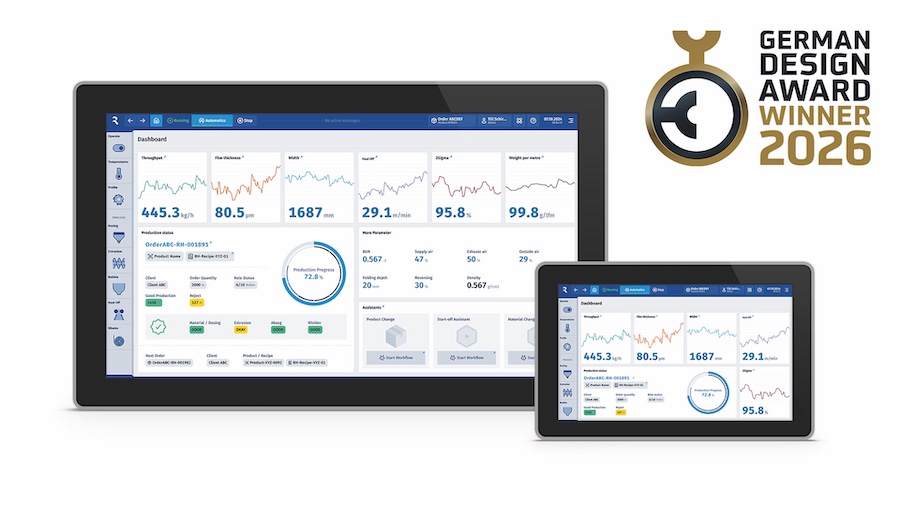

"As the driving force behind this dream project, we at encoway and Lenze are particularly excited about the new home for our growing team. We are expanding our digital and innovation lab for Industry 4.0, the DOCK.ONE, and creating an extremely attractive melting pot for innovation and collaboration by integrating it into the DHI. The highlight: We invite our customers to become part of this innovation ecosystem. Whether CPQ, IIoT or artificial intelligence, our hub network's know-how is already impressive. I am sure we will achieve radiance far beyond the country's borders with this new form of future-oriented cooperation."

Kristina Vogt, Bremen Senator for Economic Affairs, Labor and Europe:

"With the Digital Hub Industry, we have a lighthouse project that sets new standards in the cooperation between industry and science and thereby sustainably strengthens Bremen as a location and its many small, medium-sized and large companies as well as our science."

Prof. Dr.-Ing. Bernd Scholz-Reiter, President of the University of Bremen:

"As a university with strong third-party funding and research, we offer an excellent environment for successful collaborative projects. With its focus, the Digital Hub is an excellent fit for the technical profile of many of our technical degree programs and our transfer strategy. All sides will benefit from the collaboration. Researchers will be given new tasks and ideas from practice, students can get to grips with the requirements of professional practice at an early stage, and companies will benefit from access to know-how and skilled workers."

Link to the Digital and Innovation Lab for Industry 4.0 of the Lenze Group: DOCK ONE

https://www.dock.one