#Industry 4.0 / Digitalization

Earning money with data? Lenze demonstrates how.

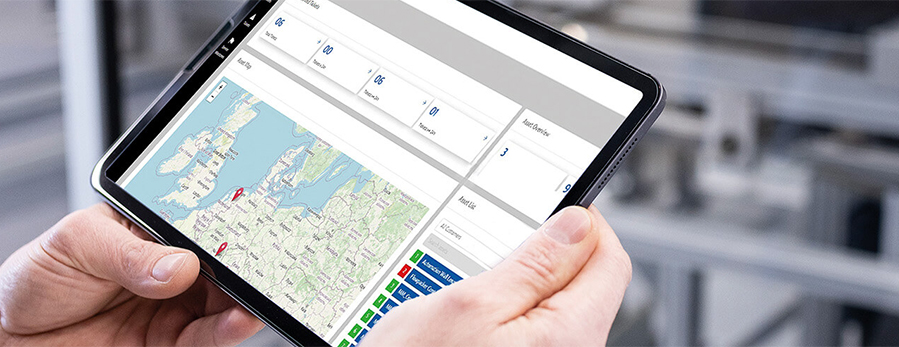

The first step focuses on transparency. Machine operators and manufacturers need to identify the machine's error, why did it stopp, and whether the issue arises e.g. from the cylinder or the motor. Thanks to the cloud-based X4 remote platform, the machine builders and their customers can jointly examine the machine in real time, identify faults, and reduce warranty costs. The data for this is derived from the PLC and can be analyzed and visualized in the cloud. Here OEE & Downtime Tracking comes into play: a digital product that enhances transparency in the production process without requiring extra hardware or sensors. The OEE is computed within the control system. Live data is displayed on an HMI - even without a cloud connection - and can be customized. The availability of these dashboards can also serve as an additional source of income for machine manufacturers.

WhatsApp for servicing is not digitalization.

The second step involves the asset performance platform, where once again, the machine manufacturer collaborates with the machine operator. Anyone who believes that a WhatsApp message from the customer to the service department represents a significant digital advancement is mistaken.

Lenze's Asset Performance Platform goes well beyond this: it stores information for all machines. The machine's structure is automatically transferred to the asset management system, ensuring that all relevant data sheets, manuals, and technical drawings are consistently available in their latest versions – even if they are not Lenze components. Information required for troubleshooting and repairs is no longer a matter of searching; it is instantly accessible at all times. This digital twin also helps in preventing errors when replacing components through asset management, thereby reducing downtimes. Ticket management takes the place of the WhatsApp message. An error ticket can be generated either manually or automatically by the machine. The service department can use the dashboard to monitor the status of all tickets and prioritize them accordingly. The machine operator employs the archived tickets to build a knowledge database.

The third step is aimed at more customized solutions. The usual number of data points from the PLC is often insufficient for predictive applications. Therefore, Lenze utilizes inverters as sensors, which provide high-resolution data at a frequency of up to 16 kHz. At this juncture, Lenze engineers collaborate with the machine manufacturer to create a data-driven product for the end customer. This could include a vibration detection system, an unbalance alarm system, or a product capable of predicting the condition of a saw or a blade. In conjunction with the Asset Performance Platform, spare parts can also be made available. This way, Lenze evolves into a comprehensive partner for the machine manufacturer and also offers development capabilities.

The fourth step involves swiftly deploying the developed models as digital products in the field. Lenze has introduced the Nupano open automation platform to keep track of the installed base, ensuring knowledge of where and in which version the algorithms and trained models are running at the edge layer.

Nupano closes the gap between the IT and OT domains.?

Lenze also provides the way for innovative digital business models through Nupano. This open automation platform enables machine builders to incorporate applications into their machines throughout the entire lifecycle and manage them effortlessly.

Nupano leverages open and established IT architectures. Even machine builders without IT expertise can create Docker-based software apps, deploy them on production machines in the field, and manage them. Since customers can access both applications and a digital twin representation of the machine on the platform, they can seamlessly integrate information technology (IT) with operational technology (OT) to generate real added value.