#Industry 4.0 / Digitalization

Asset and ticket management for higher machine availability

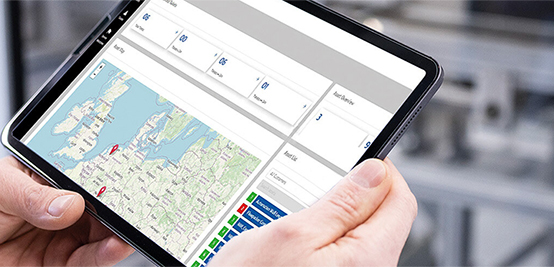

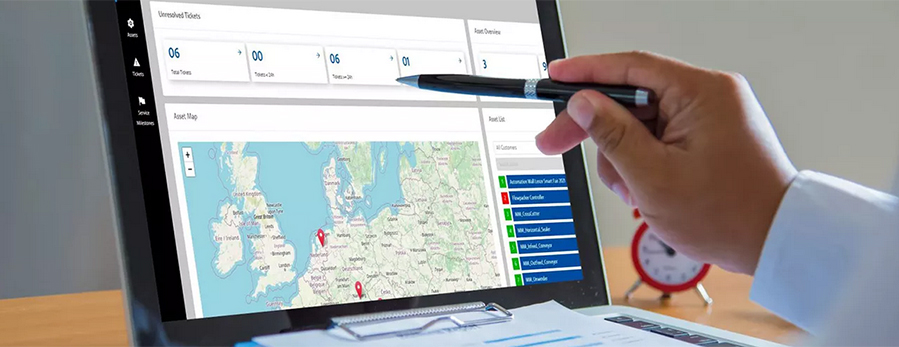

When a machine reports a fault, there is only one goal: to capture the fault as quickly as possible, fix the problem, and get the machine back up and running. Lenze Asset Management in conjunction with machine status and fault management provides effective support for keeping downtimes to a minimum through rapid troubleshooting.

Which component is installed? Is the documentation up to date? And if the model and variant are known, how do you find the serial number, the index of error messages or certain technical specifications? Despite all efforts to make processes as efficient as possible, such aspects have not yet been systematically resolved in many companies – which means the service technician loses valuable time in an emergency, resulting in the downtime lasting longer than necessary. Lenze’s digital experts have addressed this issue and, with the aid of automation and smart networking, created a solution that puts an end to the loss of time and efficiency.

Service portal for OEMs

The automation specialist has developed a portal that is directly linked to the OEM’s machines. If an error occurs, the machine can now automatically create a ticket on its own, thereby notifying the service technician early on. The ticket specifies which component is affected. This allows the model, variant and serial number to be queried, as well as the position in the machine’s topology. Incorrect information due to out-of-date documentation is ruled out: The information comes directly from the PLC, which always reflects the consistent actual status. Further technical information or additional information on the error message is just a few clicks away, without tedious searching and loss of time. Since the platform is manufacturer-neutral and complies with open standards, it is not only Lenze products that can be accessed. SICK is also already on board, allowing their sensors to be recognized and all existing product information to be made available.

But that’s not all: Via the remote function, the technician can connect directly to the machine and e.g., immediately rectify software errors or obtain more detailed information where necessary. In the case of hardware defects, a spare part can be ordered immediately which corresponds exactly to the installed part, without any mix-ups, for example due to different orientations.

Win-win situation

The time saved by the OEM, who thus provides more efficient service, is also reflected in the OEE of the plant operator when downtimes can be shortened, and service costs reduced. This makes the portal suitable as the basis for a paid service, which still brings cost benefits for the end user and even additional revenue for the OEM even though rental costs for the portal are also incurred.

The solution is multi-tenant-compatible, i.e., each OEM who books the service can customize the portal in his Corporate Design (CD). For the end user, this means that only the supplier of his machines shows, because it is no longer apparent that Lenze is behind the cloud application.

One key aspect for the attractiveness of the solution is the fact that setting it up does not require any major manual preparatory work. The identification of the devices and components installed is largely automatic and thus always up to date. The technical basis for this is provided by Lenze’s FAST Application Software Toolbox, which is now equipped with a framework that can also collect data beyond the PLC. The technology in use harmonizes the data and makes it available in a format that complies with the OPC UA communication standard. Based on such open standards, it is also possible for OEMs to develop their own digital services and business models independently of the OEM portal.

To be seen at Hannover Messe 2022 in Hall 6, Booth F21