#ITMA Asia + CITME 2024

ITMA ASIA + CITME kick-off of the KARL MAYER GROUP with high visitor response

Successful start to the trade fair

The professionals came mainly from China, but also traveled from Southeast Asia, Turkey and Pakistan.

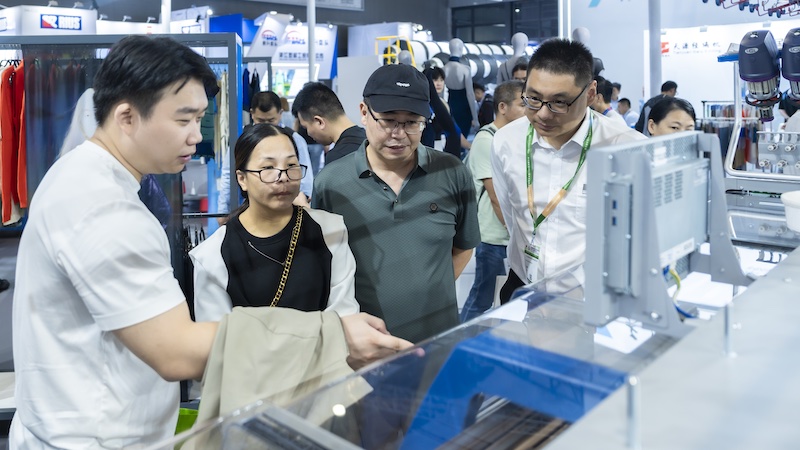

Most of the guests were interested in the innovations in the fields of warp knitting, warp preparation and flat knitting and engaged in in-depth technical discussions. One of the topics of the exchange was the question: How to compete in the strong competition under the current difficult economic conditions? The KARL MAYER GROUP provides an answer, primarily through its products. The global player's machines stand out from comparable products on the Chinese market thanks to their excellent price-performance ratio.

The warp knitting customers are particularly impressed by the performance and products of the exhibited HKS 2-S in the new gauge E 44. The highly efficient two-bar tricot machine – its output is 200 kg of textile per day - produces a wide variety of fabrics, from top layers for thick down jackets to articles for comfortable outerwear. Their E44 items are also setting trends, particularly in the hot topic of sun protection clothing. With their dense surface, they offer a high UVP factor, are also light and silky, feel cool against the skin and do not wrinkle - a performance that is of particular interest to manufacturers in the outdoor sector. Elastic 4-way stretch articles for outdoor clothing are a focus of many discussions.

Visitors generally show a great willingness to innovate. They are looking for promising applications for their products, for new fabric developments and opportunities to expand their business fields and for machines to realize their ideas. They will find what they are looking for at KARL MAYER, for example in the presentation of warp-knitted apparel fabrics for typical woven applications, comfortable sportswear articles for the growing yoga trend, delicate TEXTRONIC® articles with a uniquely contrasting interplay of transparency and plasticity and spacer fabrics for shoes and clothing.

A highlight for visitors from the flat knitting sector is the CMS 503Ki L E18. At the trade fair, the innovative machine will be producing a chic ladies' scarf with a lace-like look that is sure to attract attention and is representative of the design potential available. With a working width of 50”, the STOLL machine produces items with an unlimited variety of patterns for a wide range of full fashion applications and with an extended size range. It also offers high productivity. The CMS 503Ki L thus offers everything that manufacturers need in their volatile, price-driven volume markets: a fast response to rapidly changing trends and an excellent price-performance ratio. The CMS 703 ki knit and wear in gauge E10.2 and the ADF 530-32 ki FLEX E7.2, which are likewise on show, are also closely surrounded by trade fair visitors. Both machines also focus on speed in volatile markets.

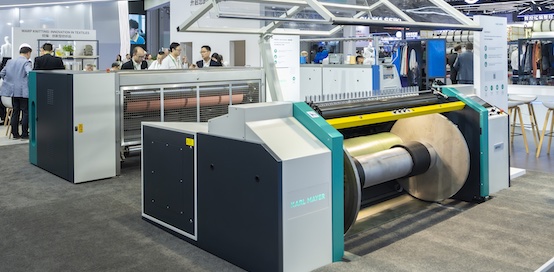

Customers from the warp preparation sector are impressed by the WARPDIRECT. The universal beam warping machine of the latest generation scores with an excellent price-performance ratio, quality of its products and speed. The warping speed reaches a unique 1,200 m/min. The high-quality warp beams produced enable less yarn waste in the sizing processes, lower costs in warp preparation and maximum efficiency during processing in the weaving mill. Other advantages include high operational reliability and less maintenance work.

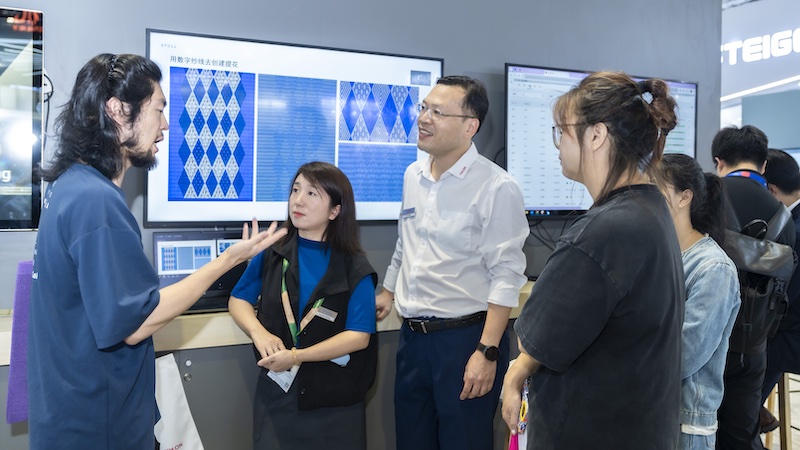

There are also many discussions about KM.ON's digital solutions, in particular Digital Production Management (DPM) as a pioneering solution for the shopfloor organization of warp knitting mills, the Quality Monitoring System (QMS) for AI-based quality management on warp knitting machines and the STOLL PPS powered by KM.ON tool for controlling, planning and optimizing flat knitting production. The design software of the CREATE family is also the subject of many meetings. The exchange focuses on the realization of the designed patterns in the production phase and the exploitation of the various potentials. The virtual modeling of the yarns is particularly well received.