ITMA 2023

ITMA 2023: Mahlo looks back on successful trade fair

"We are more than satisfied with the way ITMA went," says Mahlo CEO Rainer Mestermann. "After the events of the last few years, we could not automatically expect such a large crowd at our stand and at the entire fair." The interdisciplinary team at the stand in Hall 18, consisting of sales, application technology and service staff from Germany as well as the international sales and service partners, received visitors from all parts of the world. "Of course, there was a strong influx from Italy, but Turkey, India, Bangladesh, Pakistan and Latin America were also particularly well represented, in our estimation." The number of guests from China was somewhat lower, but this is understandable, as ITMA Asia is due to take place there later this year.

At the Mahlo stand, guests could inform themselves about the product portfolio and the latest developments of the machine manufacturer for process optimisation in textile finishing. The visitors felt very well looked after by the internal and external team. "A workshop preceding the ITMA at the headquarters in Saal guaranteed that all contact persons of the target markets were up to date with the latest developments." This expertise was then in demand virtually around the clock.

Energy saving methods on top of clients’ agenda

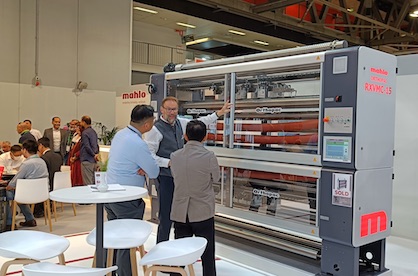

"The topics of quality, energy saving and return on investment were at the top of the agenda for many visitors," says Stephan Kehry, Textile Product Manager. This was accompanied by great interest in data management and data recording. "Our new X-Series concept for forward control of knitwear with strong distortions was particularly in focus." The Orthopac RXVMC straightening machine, which was presented for the first time in Milan, can remove distortions in textile fabric webs even faster and more precisely. The exhibit was delivered to a customer in Italy after the fair.

Mahlo’s new X series concept convincing customers

"With the new straightening concept, special attention was paid to the straightening mechanics and their interaction with the analysis electronics of the scanner system," explains Head of Sales Thomas Höpfl. Two individually controlled and driven straightening modules with a total of four bow and three skew rollers ensure that the correction of bow and skew distortions takes place in small steps. The control concept is also new. A scanner group at the infeed of the straightening machine detects distortions even before they reach the correction rollers. This way, the rollers are brought directly into position and the fabric is corrected from the very first centimetre. A scanner group at the outlet also detects possible residual distortion, which is corrected at the second straightening module. This enables an even more precise and faster response when it comes to reacting to rapidly changing distortions. The Orthopac RXVMC therefore shows its full strength when straightening knitwear and distortion-sensitive fabrics. It guarantees higher quality goods and thus less waste. "Especially at a time when our customers are under increased cost pressure and competition in the textile industry is intensifying, our new concept has been convincing."

Not only the exhibits proved to be a visitor magnet, but traditionally also the Mahlo bistro with its Bavarian specialities. With the successful combination of high-tech and Bavarian down-to-earthness, Mahlo's trade fair appearance at ITMA 2023 was impressive.