#ITMA-Asia + CITME-2016

KARL MAYER reports positiv results halfway through ITMA ASIA + CITME

Manufacturers of technical textiles have also been delighted at being given some new ideas on the subject of lightweight constructions on KARL MAYER’s stand in Shanghai. This company is also showing a highly productive sectional warping machine for weaving preparation, and an innovative sizing system.

To coincide with the exhibition, visitors to the fair can also attend an in-house show at KARL MAYER (China) in Wujin, Changzhou, which is showcasing an extensive range of products.

The focus of the in-house show is on the production of lace, and a fundamental new development, the OJ 59/1 B, is setting new standards for multibar jacquard machines in terms of the cost:benefit ratio. This new machine is the first machine in the new LACE.EXPRESS series. It can produce large volumes of fashionable lace for the rapidly changing outerwear market, and is just as efficient as the JACQUARDTRONIC® Lace machine, but is much more productive.

In Wujin, Changzhou, KARL MAYER is also showing a new double-bar raschel machine for producing fashionable shoe designs, and a direct warping machine for warp knitting preparation, which features a universal, hybrid operation. The show of the innovative machines has been very well received. It attracted nearly 200 registered visitors only on the first two days. A free shuttle service is available for transferring visitors from the fair to the in-house show.

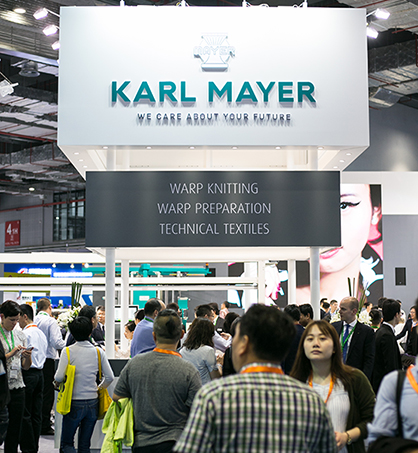

Pic: Visitors to KARL MAYER’s stand at ITMA ASIA + CITME