#ITM 2024

Fruitful discussions and an attention-grabbing innovation showcase

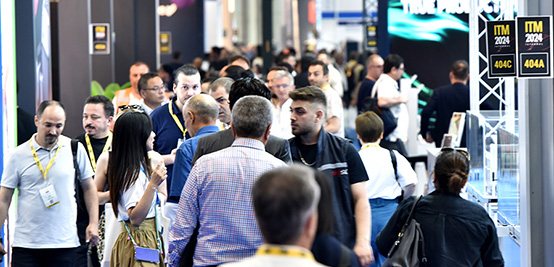

The positive outcome included numerous new contacts - 22% of the registered guests were first-time visitors - and an almost consistently high number of Turkish visitors as at ITM 2022. Above all, however, there was a high-quality professional exchange with dialogue partners, most of whom had specific concerns.

"We had many in depth discussions, mostly about the difficult economic situation. Our customers are currently looking for ways to reduce their costs and increase the efficiency of their production. The solutions we presented in the areas of machine technology, digital solutions, service and textile innovations gave our customers a lot of valuable insight for their business. It is also relevant to note that with the quick changing requirements of retailers, machine flexibility is becoming as important as speed. " says Toros Greenhalgh, Managing Director of the Turkish subsidiary of the KARL MAYER GROUP, which has only started local operations this year.

KARL MAYER TURKEY will meet increasing customer demands for after-sales service, spare parts (Care Solutions), and academy, in the sectors of warp knitting and warp preparation, while KARL MAYER’s long-standing regional representative ERKO focuses on machine sales.

Qualified talks, strong dialogue partners from the warp knitting industry

"Quality counts! There were no walk-in visitors, but almost 90% of our active customers came to our booth, mostly to discuss specific projects and machine sales," summarised Bastian Fritsch, Senior Sales Manager of the KARL MAYER Warp Knitting business unit. Particularly in the light of targeted anti-dumping measures and the results of the last municipal elections, a positive trend is emerging on the market after the past difficult months. However, it is not possible to say how sustainable this development will be. Some major industry players want to renew their production capacities and the order situation of many warp knitting customers is good overall, albeit with reduced profits due to cost increases, concluded Bastian Fritsch. A highlight for his audience was the displayed HKS 3-M ON PLUS, which impressed shoe and outerwear manufacturers, as well as interested customers from the curtain sector, with its flexibility, the new Advanced Feeding Control (AFC) and a coarse gauge.

The Care Solutions team shares the positive view. "We had many interested visitors for our after-sales offers. In particular, our Care Solutions packages, which cover the topics of spare parts and service calls, e.g. for gauge conversions, were very well received," says Axel Wintermeyer, Vice President Care Solutions at the KARL MAYER GROUP.

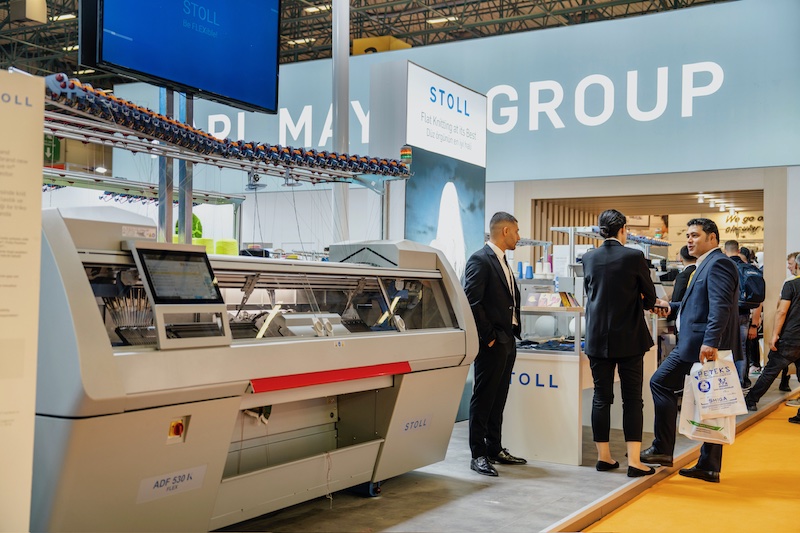

Flat knitting machines with market focus

STOLL Sales Manager Lutz Vogel is also optimistic after ITM 2024. "Our customers were interested in almost all the products on show and we had very effective discussions with them. The joint dialogue showed that business will pick up as soon as the situation improves," says the market expert.

If the market recovers, STOLL has the right offer for every need, from the efficient economy machines CMS 502 and CMS 503 for the price-sensitive volume business shown at ITM to high-class ADF technology, especially for success in niche markets. The ADF Flex presented in Istanbul was a particular crowd-puller. Thanks to the automatic adjustment of the needle beds in relation to each other, customers can knit even tighter or looser than before and thus produce tighter cuffs or insert much thicker yarn, for example. The STOLL team also received important market feedback on the ongoing development of a brand new machine. The newcomer is intended to make customers significantly more competitive under today's conditions and will be launched towards the end of this year.

A platform for a successful market presence

ITM was also an important opportunity for the Warp Preparation, Technical Textiles and KM.ON divisions to showcase their presence, identify market trends and present solutions for the success of their customers.

"For our warp preparation customers, the topic of energy efficiency is extremely important, both for cost and sustainability reasons. Our new CASCADE system, which relies on the recycling of process steam, is an important contribution to this," says Dieter Gager, Vice President Sales of the Warp Preparation business unit at KARL MAYER. An important topic for his customers were the solutions for the denim industry, including the sustainable dyeing technology BLUEDYE, for which the KARL MAYER GROUP has just received the German Award for Sustainability Projects 2024 in the category "Production".

The Technical Textiles team was able to hold good discussions about its machines with weft insertion for the production of construction and geotextiles. There were also a number of discussions about the performance of KARL MAYER multiaxial machines, especially with representatives from the wind power industry. KARL MAYER has a particularly interesting composite machine for them in the product range with the new MAX GLASS ECO, which is optimized in terms of price-performance ratio.

KM.ON had successfully launched two advanced solutions for the warp knitting industry: the Digital Production Management (DPM) for significantly simplifying management and control of the production processes and the AI driven Quality Monitoring System (QMS) as a revolutionary solution for fabric quality management on warp knitting machines. Additionally, the digital solutions for the flat knitting industry – the production planning system PPS and CREATE DESIGN, which accelerating the development and design process of knitwear generated a lot interest and were topics of many in-depth technical discussions with the customers.