#ITM 2024

Marzoli showcases roving frame FTM320 at ITM 2024

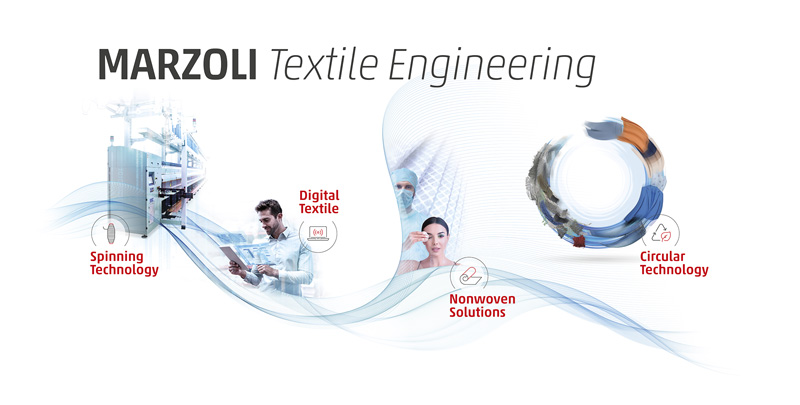

The concept of "Textile Engineering" - a key part of the Marzoli identity - encapsulates their goal to produce innovative textiles solutions. They also work closely with their customers, supporting them at every stage in the acquisition and operation cycle: from preliminary studies to plant construction, line start-up, production optimisation, plant management and digitalisation. It is this combination that marks out Marzoli as a unique global partner in the creation of manufacturing solutions and underscores the mission to shape the future of the textile industry, the company states.

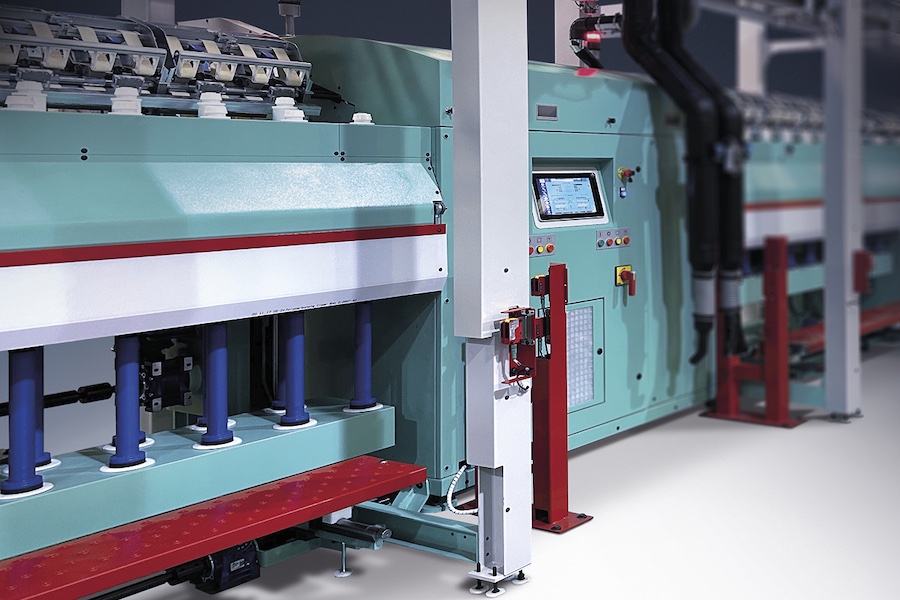

At ITM, the focus will be on the new Roving Frame FTM320: The longest machine. The latest and greatest.

The innovative roving frame with a central headstock and independent double side modules works simultaneously, to allow spinners to increase efficiency by up to 5%.

The long-term vision and innovative digitaljourney that Marzoli and Camozzi Group designed several years ago, have made it possible to develop the first A.I. enabled':":' platform dedicated to the textile industry. This, combined with solutions for remote maintenance, advanced software for the integration of management tools and apps for the analysis of cotton waste, allow spinners to benefit from a significant increase in production (up to 5.5%) and efficiency (up to 8%), while at the same time reducing maintenance and failure costs by up to 30%.

At ITM, a section of the booth will be dedicated to nonwoven solutions, providing visitors the chance to learn more about Marzoli's tailored offerings for this sector. Special emphasis will be placed on the range of applications, including wipes, medical-surgical, disposable, and filtration products.

Since 2012, Marzoli has focused research on continuous innovation in the mechanical regeneration of textile fibres for its customers. This event will be, again, anopportunity to highlight the developments made in this pressing and fundamental change in the textile industry.