#ITM 2024

High quality nonwoven lines with increased reliability and reduced operating costs

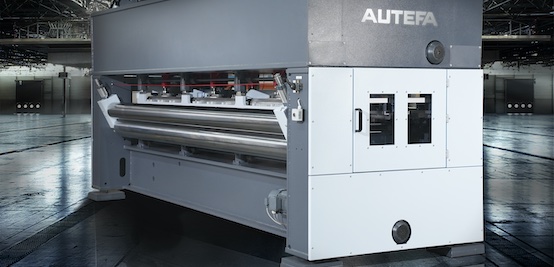

As a leading supplier of turnkey nonwoven systems and machinery, AUTEFA Solutions offers comprehensive solutions including needle punching lines, aerodynamic web forming lines, spunlace/wetlaid lines and thermobonding lines.

AUTEFA Solutions is pleased to showcase sustainable applications with airlay lines and demonstrate significant energy optimization in oven and dryer technology. The company will also highlight its expertise in complete needle punching lines tailored for geotextile, filtration and artificial leather applications. AUTEFA Solutions supports the principles of the circular economy by optimizing the entire life cycle of textile fibers through recycling and reuse, thereby reducing resource consumption.

AUTEFA Solutions Baling Technology

Fiber baler - high performance in fiber production

AUTEFA Solutions is proud to be total fiber production solutions partner for its customers. The product range is designed to support the entire production process including fiber handling, baling press, bale transport and storage in specialized bale warehouses.

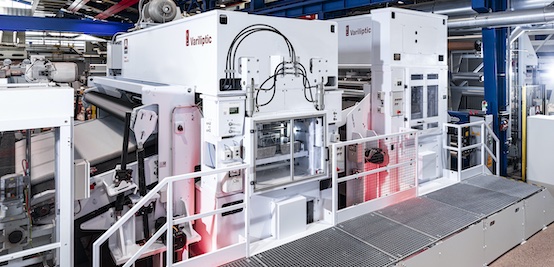

Bale handling solutions exceed expectations with features such as strapping, automated labeling and sorting to ensure the fiber production process is as efficient as possible. Weighing, stacking and storage options are available in both block and rack systems, allowing you to choose the solution that best suits your needs.

AUTEFA solutions to optimize every step of the fiber production process for maximum efficiency and reliability.