#Dyeing, Drying, Finishing

New technology in a proven system

There are several reasons why determining these two parameters is so important: Every product, regardless of the sector, has to meet certain requirements that have been previously defined to ensure proper functioning. If the real values do not correspond to these specifications, this can affect the performance. If, for example, a filter mat is too thin in pond systems, it does not catch enough dirt particles and reduces the water quality. Incorrect residual moisture values not only affect the product quality but also the energy consumption in the entire line. For example, if Spunlace nonwo- vens are overdried, this results in unnecessary waste of energy – with negative consequences for the environment and the manufacturer's wallet.

New sensor variant for even more applications

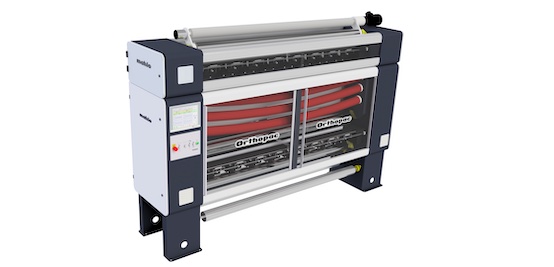

To measure and control basis weight and moisture even more reliably, Mahlo has added a new sensor variant to its proven Qualiscan QMS-12 quality measurement system. The Infralot IMF uses near infrared technology to determine the two essential values. For the first time, the sensor is available as the Infralot IMF-T version in the transmission process, which is used for thick materials and thus covers an even wider range of applications than before. The previously proven reflection method of the Infralot IMF-R has been updated to the latest state of the art.

Principle of operation

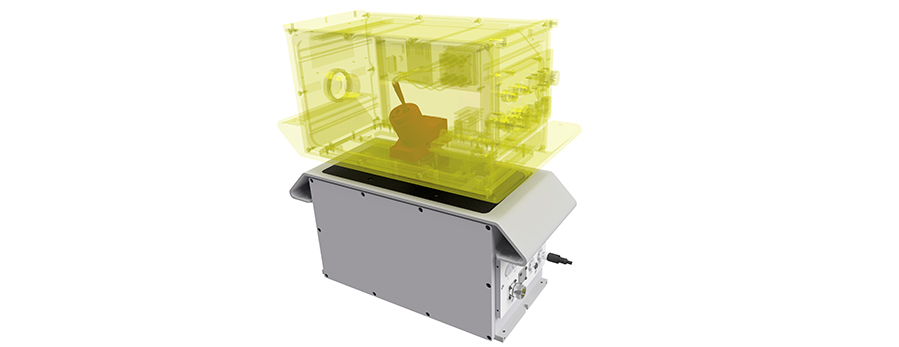

Water and materials such as cotton, PET or paper absorb light in the near infrared range. They are distinguished by different spectral ranges and can thus be differentiated. By measuring the reflected or transmitted light energy by means of optical evalu- ation, the Infralot IMF determines the moisture content and basis weight of the products. The NIR sensors of the Infralot IMF series are based on a classic filter measuring principle.

However, this is updated with the very latest optical components and in accordance with the most recent trends in optical measuring technology. With conventional filter wheel systems, the wavelengths for dry (reference) and wet conditions are measured with a time delay. This can lead to measurement inaccuracies, which are particularly disadvantageous for inhomogeneous products such as thin non- wovens.

No filter wheel

Mahlo's new simultaneous filter measures all wavelengths simultaneously and at the same spot without rotating filter wheel. Instead, the light is distributed simultaneously to six detectors. This eliminates measurement inaccuracies and allows true same-spot measurement of reference and absorption resonances.

Variants suitable for requirement

The variant used depends on the application. With the double-sided transmission sensor Infralot IMF-T product can be measured with penetrating infrared radiation. Transmission measurement is especially needed for thicker materials and when the overall composition of the material is of interest. Measurement for nonwovens is pos- sible with a basis weight between 10 - 500 g/m2. For paper, moisture can be deter- mined between 0 to 20%, basis weight up to 250 g/m2.

Measurement with IR reflection is used primarily to determine the top layer or coating without measuring the underlying substrate material. The measuring tolerance of the basis weight is between 10 and 60 g/m2 for nonwovens. In paper coating, all polymers, adhesives, resins and water-based coatings can be determined.

Product highlights

- Non-radioactive

- Static simultaneous filter – simultaneous measurement of all wavelengths

- Smart sensor with microprocessor?

- High spectral resolution

- Insensitive to product flutter and soiling