#Dyeing, Drying, Finishing

SAATI Germany optimists production with Mahlo technology

The globally active SAATI Group produces filter fabric for blood transfusion devices, aramid fabric for bulletproof vests and functional fabric for mobile phones and tablets, among other things. SAATI is known for its high precision and quality, which is maintained at all stages of production. The high quality standards are particularly important as many of the materials produced have to fulfil vital functions, such as in medical technology or the security industry.

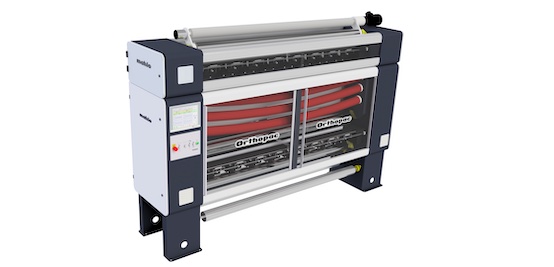

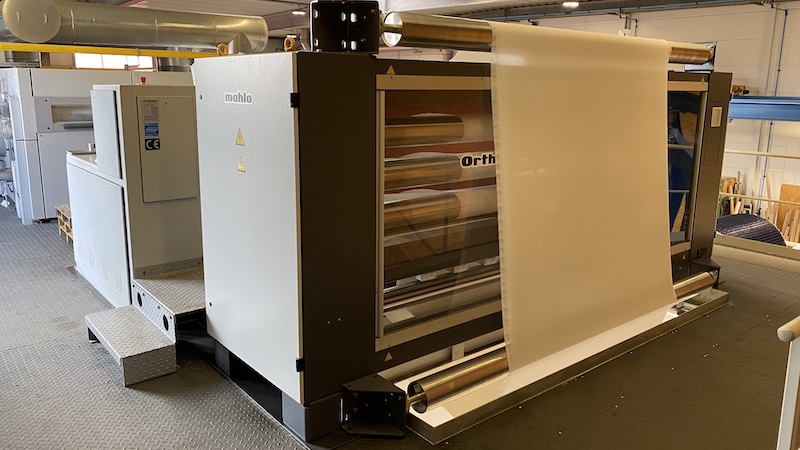

The installation of a Mahlo distortion control system Orthopac FMC-15 and a Famacont PMC-15 yarn density meter in the outfeed of a stenter frame was a further step in this optimisation process.

As Saati produces highly technical fabrics, the exact thread count (up to over 300 F/cm) is an essential quality feature. The PMC-15, a camera-based measuring system, can continuously record and log this parameter. At the same time, the FMC-15 records residual distortion and contributes to the elimination of so-called back sheet distortion in the fabric by automatically controlling the take-off roller of the stenter frame. This ensures the consistently high quality of the end products and reduces potential sources of error.

The investment in these systems proved so successful that SAATI initiated the next stage of process optimisation in 2024. „With the installation of an Orthopac GRVMC-15 straightening machine before the infeed of the stenter frame, we have further perfected the control of fabric quality,“ says Operations Manager Thomas Brockmeier. The heavyweight among the Mahlo straightening systems with a working width of 2,800 mm enables SAATI to correct skew and bow distortions in the raw fabric even before the stenter frame. This is because a weft yarn that is only slightly skewed or curved can render the fabric unusable or visually unfit for use.

By combining the GRVMC-15 with the FMC-15 already installed in the outfeed, SAATI now has a fully automatic system that offers maximum monitoring and control options. The co-operation of these two technologies enables the company to deliver precisely shot-straight items. „I am delighted that we were able to complete the project so successfully,“ says Brockmeier. „For us, this means an enrichment in terms of quality and production reliability.“

The successful integration of Mahlo technologies not only strengthens the production capacities of SAATI Germany, but also emphasises the company‘s high standards for the quality and precision of its products. SAATI is thus setting a further example of innovation and efficiency in the textile industry and securing a decisive competitive advantage in the global market.