#Digital Printing

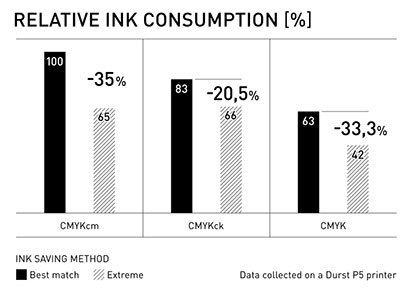

Save up to 35% ink with Durst Workflow ink save tool

Designed for Durst printers, Ink Save has optimized presets to ensure the optimal ink saving configuration. Durst Workflow Ink Save is now also available for third party printers to maximize savings and ensure color accuracy across your entire printing devices.

Discover Durst Workflow Ink Save tool

How does the Ink Save tool work?

You don’t need to be a color expert to save on ink with Durst Workflow: its integrated powerful engine automatically calculates the color combination that reduces the amount of ink printed on the substrate. The Ink Save tool adjusts the ink consumption of all colors in your printer and compensates with black to achieve optimal reduction of your total ink consumption. Check ink consumption before printing: calculate and compare the ink consumption of your job in advance and compare the amount of ink usage with/without the feature or with different ink save modes to find the solution that best suits your needs. No re-profiling is needed.

In addition, Grey Component Replacement (GCR), being one part of the used algorithms, enables the right balance between ink savings and smoothness. In Durst Workflow the CMY values that add up to gray in the tone scale are replaced with black ink. The use of light black ink further supports this GCR approach, as the reduced contrast of light black allows for the best possible uniformity by replacing CMY. It results in less ink consumption, consequently thinner ink layers and optimized drying, which is especially valuable for high-speed printing and is also reflected in simplified post-printing processes. This function is as well applied automatically, so you don´t have to change it manually.

Why should you use this feature?

In this day and age, attention to issues around environmental sustainability and resource saving is imperative, as economic development and sustainability increasingly emerge as strongly related issues. Through the Ink Save tools, we help our customers reduce ink consumption and production costs by offering a choice of 3 different ink saving levels: low, medium and extreme. By using the extreme level, it is possible to save up to 35% on ink consumption.

Besides the significant environmental advantage of this, it is also a considerable figure for our customers' return on investment (ROI), which also helps reduce the total cost of ownership (TCO).