#Associations

A unique product created with Swedish innovation

Just as significantly, these technologies are providing the tools to differentiate in highly competitive fields, as is demonstrated by a recent project initiated by TMAS – the Swedish Textile Machinery Association – for the highly automated production and decoration of a unique tote bag.

Plastic reduction

Back in 2015, the European Parliament reinforced legislation to encourage an 80% reduction in the use of conventional single-use plastic carrier bags by 2025.

The initiative immediately had broad public support, effectively encouraging a basic and widespread change in consumer behaviour. As a result, the consumption of disposable plastic bags has fallen significantly, along with a corresponding reduction in the waste they create.

There has also been a swing towards durable woven shopping bags which in the past have been labour-intensive to produce cheaply, as a result of the cutting and sewing involved.

Thanks to Swedish innovation, this is no longer the case.

Fully automatic

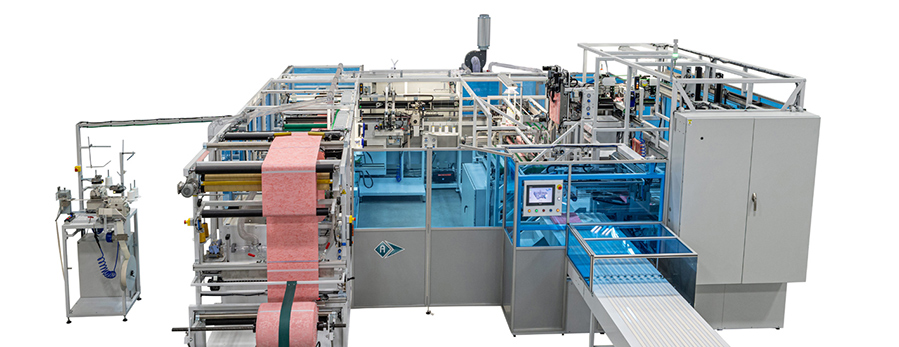

TMAS member Automatex has developed a fully automatic tote/consumer bag sewing unit which can produce fully finished bags in heights of between 35-80cm and widths of 30-80cm. The machine is configured to carry out all the necessary automated operations including hemming, handle insertion, cutting, labelling, bag forming and gusset forming, which previously had to be carried out manually.

Its output is some 540 units an hour, introducing a completely new cost paradigm.

The resulting bags, however, are still plain and uniform at this point, and with products that are intended to be used for as long as possible, personalisation is the key. Unique designs work to ensure purchasers are likely to become more attached to their products – and are happy to pay a little more for them in the first place.

Instant colouration

In order to add decorative appeal, another TMAS member company, Coloreel, became involved in the project.

Coloreel continues to secure multiple orders for its instant thread dyeing technology for high-speed decoration and embroidery – notably with the fast-rising new generation of online merchandisers and brands for whom mass customisation and produce-on-demand sales are the key. The addition of a distinctive embroidered design to the tote bag using Coloreel’s technology took the product to a new level of attractiveness, as a further showcase for Swedish innovation.

The technology enables the high-quality and instant dyeing of a textile thread while it is actually being used in embroidery production. It can be used with any existing embroidery machine without modifications. Additionally, this technology makes it possible to produce gradients in an embroidery design, as demonstrated by the TMAS logo and the text in the image.

Advanced rapid colour formulation software and high-speed drive technology allow a single needle to carry out what it previously required many multiples of them to do – and with much more consistent stitch quality.

By instantly dyeing a recycled white thread during production, the system enables complete freedom to create unique decorations and embroideries without any limitations. Colour changes along the thread can either be made rapidly from one solid colour to another, or gradually, to make smooth transitions or any colouring effect desired.

This provides big benefits when it comes to both sustainability and design creativity.

Potential of Swedish innovation

“Coloreel’s designs on the batch of bags produced on the Automatex machine are truly outstanding and have been turning heads wherever they appear,” says TMAS secretary general Therese Premler-Andersson. “The collaboration really emphasizes the positive potential of the latest Swedish digital textile technologies which are enabling companies to generate new revenue streams wherever they happen to be located.”