Yarn & Fiber

Toray creates world’s first porous carbon fiber with continuous pore structure

New material could benefit environment by enhancing performance of advanced gas separation membranes

The company will keep pushing ahead with R&D for this new material to foster carbon recycling, collaborating with other entities in developing applications to sustainably tap hydrogen energy and shrink environmental footprints.

Absorption- and adsorption-based facilities conventionally separate carbon dioxide, biogas, hydrogen, and other gases. The issue with such setups, however, is that they are large and consume a lot of energy, resulting in heavy carbon dioxide emissions. Gas separation methods employing membranes have thus attracted considerable attention. But despite ongoing research, no membranes have yet combined satisfactory gas separation performance and durability.

Toray’s new material is chemically stable because it comprises carbon, and offers outstanding gas permeability. The material employs thin, flexible fibers, so when it is used to support gas membranes a module can house many of them. Modules can thus be compact and light. Such support makes it possible to combine a range of gas separation layers.

Toray looks to contribute to the swift commercialization of advanced separation membranes that are vital to materializing eco-friendly natural gas and biogas purification and hydrogen production.

Toray innovated its new material by combining its outstanding polymer technology with its market share-leading carbon fiber technologies and water treatment and other separation membrane technologies.

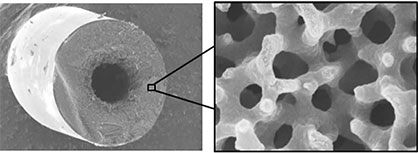

Harnessing its polymer technology enabled the company to create a porous carbon fiber with uniformly continuous pores and carbon. It is possible to set nano- through micro-level pore sizes for porous structures. Another possibility is to create a hollow fiber-shaped porous carbon fiber in the center of a fiber.

Prospective applications leveraging the excellent adsorption of Toray’s new material include electrode materials and catalyst carriers (base substances for fixing other substances) in high-performance batteries.

Toray will open its R&D Innovation Center for the Future in December this year. The new facility will serve as a global headquarters for strategic innovations by engaging with academic institutions and key partners from diverse fields. The company will collaborate with several partners in efforts leveraging its new material in a drive to commercialize more advanced gas separation membranes.

Under the Toray Group Sustainability Vision, the company looks to keep developing technologies that help materialize low-carbon economies by 2050 by contributing to resolutions of environmental, resources, and energy issues.