#Weaving

Vandewiele Group: Innovation across the textile value chain at ICFE Istanbul 2026

Under the philosophy “textile innovations together,” the Group unites its companies and technologies to deliver end-to-end value — offering manufacturers a seamless path from yarn to finished carpet.

Boost carpet production with RCF – high-speed carpet weaving with Fast Creel

The RCF high-speed carpet weaving machine now reaches weaving speeds of up to 225 rpm. Equipped with the innovative Fast Creel system, it enables bobbin changes during production, eliminating downtime and maximising output. Traditional pile droppers and weights are no longer required, allowing faster creel changes and full bobbin utilisation for continuous, stable production.

Automatic threading and improved bobbin handling reduce operator workload, while Vandewiele’s tight-end detection system protects yarn quality and prevents breakage. The result:

- less waste

- superior carpet quality

- higher production speed

- enhanced operational flexibility

The RCF with Fast Creel offers a smarter, faster and more flexible weaving process — delivering high quality at high speed.

Achieve maximum speed and precision with HST – high-speed tufting technology

Vandewiele continues to redefine tufting with its High Speed Tuft (HST) platform, introduced at ITMA 2023. The HST is the fastest and most advanced tufting machine available, operating at up to 2,500 rpm for loop pile and 2,000 rpm for cut pile carpets.

Its fully digital motion control makes the HST unique. Servo-driven components store machine settings as design parameters, enabling instant, automated adjustments for each pattern, reducing changeover time and ensuring consistent quality. Individual Looper/Hook Drive technology and optional sliding needlebars provide flexibility, precision and expanded design possibilities.

To support efficiency, the Vandewiele Tufting Sensor (VTS) offers real-time yarn break detection. Built in-house with piezoelectric technology, the VTS delivers high accuracy, modularity and full HMI integration on Vandewiele tufting machines, without requiring additional hardware.

Carpet weaving with HCE3+1500 – advanced handlook performance and efficiency

The new HCE3+1500 sets a benchmark for creativity and performance in today’s handlook market. Key benefits include:

• expanded design freedom through new binding options and seamless pole transitions

• creative precision, enabling direct writing in the carpet without mirror effects

• reduced yarn consumption through ground effects

• improved productivity when pointing cors in the pile surface

Combining proven reliability with advanced features, the HCE3+1500 supports highly detailed handlook carpet designs.

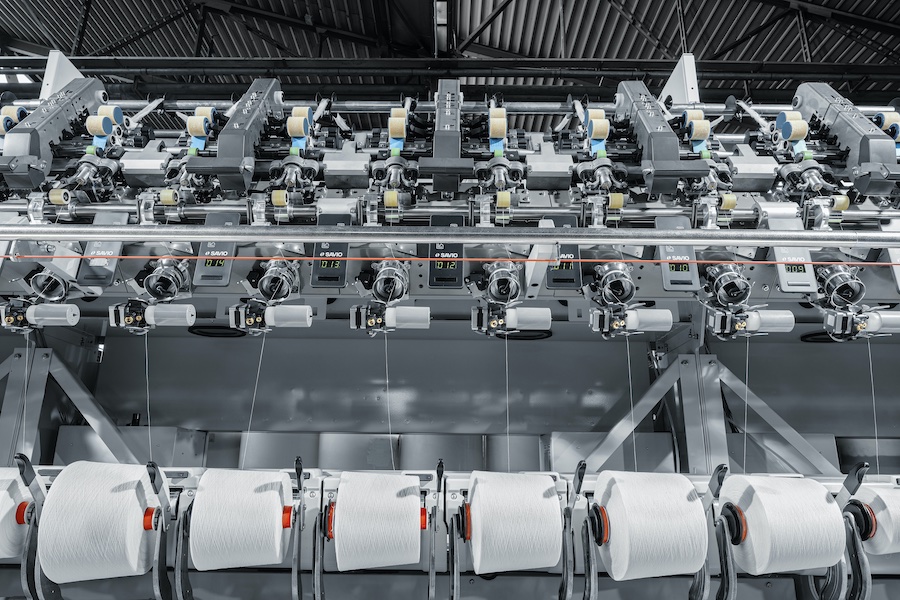

Air-jet excellence with Savio Lybra Smartspinner® – where spinning performance meets carpet innovation

At ICFE 2026, Savio Macchine Tessili highlights its role as a pioneer in spinning technology with the presentation of the Lybra Smartspinner® air-jet spinning machine. Designed for flexibility, efficiency and high yarn quality, Lybra sets a new benchmark in air-jet spinning and supports the growing demand for performance and sustainability in yarn production.

As part of the Vandewiele Group, Savio contributes to a broader synergy across the textile value chain. Vandewiele’s integrated portfolio connects expertise in spinning, weaving, tufting and finishing, offering customers a consistent pathway from yarn to carpet and flooring solutions. This collaboration demonstrates how innovation and integration enable the industry to respond to global challenges through:

- efficiency and quality — consistent yarn properties supporting downstream processes

- sustainability — reduced energy consumption and optimised resource use

- value chain synergy — connecting spinning excellence with advanced carpet technologies

By presenting Lybra within the Vandewiele framework, Savio shows how combined technological innovation can shape the future of textiles. ICFE visitors can explore how this integrated approach supports a connected, sustainable and competitive textile industry.

Vandewiele invites visitors to meet the team at the International Carpet and Flooring Expo in Istanbul, Hall 3 – Stand 332B, to discover the latest innovations, developments and highlights.