#Weaving

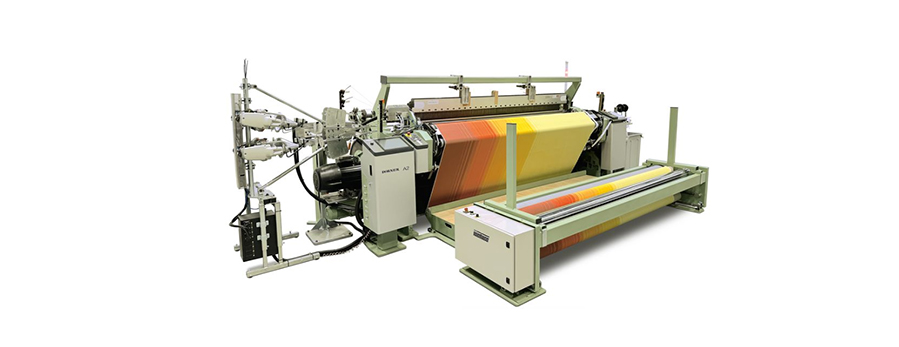

DORNIER presents new A2 air-jet weaving machine for the first time at ITMA

When DORNIER introduced the A1 air-jet weaving machine in 1989, a new era of weaving began – not only for the weaving machine technology leader, who has been manufacturing weaving machines since 1950. Since then, weaving mills around the globe are using DORNIER weaving machines to produce the finest curtains, multi-width jacquard table linen, robes made of African damask, high-quality suits, but also tire cord or airbags from various materials such as wool, cotton, silk, worsted yarn or polyester. It is not without reason that the insertion system, which accelerates the weft thread up to 280 kilometres per hour, is still considered the most flexible in the world. At ITMA, the largest international trade fair for textile and clothing technology, DORNIER is now presenting the new A2 air-jet weaving machine. Its sale starts with immediate effect. "The A2, equipped with many new functions, raises the efficiency, flexibility and reliability of fabric production in the sectors of clothing, home textiles and technical textiles to a completely new level," says Wolfgang Schöffl, Head of the Weaving Machine Product Line at DORNIER.

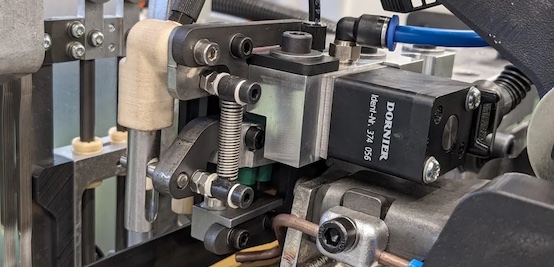

Better operating efficiency with intelligent electronics?In order to produce fabrics even more efficiently, the new A2 air-jet weaving machine features numerous electronic control systems. They continuously monitor and control the reliable weft insertion (ServoControl®-2), the nozzle valves (EcoValveControl+) and the compressed air supply (Electronic Pressure Monitoring and Electronic Pressure Regulation). This form of intelligent production monitoring not only increases operating efficiency and reduces downtime – it also permanently reduces the consumption of air and energy. "Under sustainability aspects, it was important to us to further noticeably increase the energy efficiency of the A2 compared to the proven predecessor model," explains Schöffl. In addition, thanks to the electronic warp let-off device, the warp tension on the A2 can be regulated automatically; optical and electronic warp stop motions ensure consistently reliable control of the production process.

More digital, easier to operate & faster to change over?The scope of digitisation has also been significantly extended on the A2. With the redesigned and even more user-friendly DORNIER ErgoWeave® operating panel, the personnel has an optimal overview of the fabric production at all times. Via the high-resolution interface, data on the machine, articles and weft material can now be monitored even better on the A2 – this shortens changeover times and optimises reproducibility. DoXNet software networks weaving machines and provides a user-friendly production overview. DoXNet does not require Internet access – the customer thus has full control over sensitive production data. With the DORNIER DoXWeave control desk, weaving machine data can be managed centrally – remote access to networked weaving machines is also possible. Via the myDoX® customer portal (powered by SAP HANA), which is based on state-of-the-art database technology, customers can directly order DORNIER original spare parts 24/7, access user manuals and view their current and previous orders.

Innovation based on proven technology?There is a simple reason why not everything on the A2 has been redesigned: Proven quality features of the A1 have been maintained. These include, among others, the options for setting an ideal shed geometry, along with gentle DORNIER air-jet weft insertion, the patented maintenance-free direct drive DORNIER SyncroDrive®, as well as long-life components requiring little maintenance. The unique solutions of the selvedge forming devices as well as the wide spectrum of materials and articles complete the range. "When it comes to new developments, it is not always easy to find the optimum balance between the tried and tested and the new," says product line manager Schöffl. "With the A2, we have succeeded in doing just that."