#Weaving

DORNIER initiates mask development with the German Institutes for Textile and Fibre Research (DITF)

This initiative creates the prerequesites for setting up the development, testing, approval, start-up production and cleaning service for reusable medical face masks within 4-6 months together with well-known industrial partners from the region and the Hohenstein Test Institute. The project, together with two other outstanding corona projects, was selected from 120 applications submitted nationwide and is supported by the Ministry of Economy, Labour and Housing with 195TEuro.

The supply situation for medical face masks has now stabilized; there is no longer an acute emergency situation as at the beginning of the Corona pandemic. Nevertheless, face masks are still a scarce commodity. The supply situation for protective equipment is extremely tense due to global demand. In order to avoid supply bottlenecks in the future, pragmatic solutions are being sought which, in cooperation with regional textile machinery manufacturers and textile producers, guarantee a secure supply in Baden-Wuerttemberg and make the state independent of supplies from Asia.

At the same time, it is important to further improve the wearing comfort and protective function when developing new masks. For the most complete protection possible, the masks must fit comfortably and tightly in the cheek area. There is currently still considerable potential for optimisation. In addition, conflicting requirements regarding air permeability and microbial filtration efficiency must be met. Last but not least, ecological aspects that speak against the use of disposable products must be taken into account.

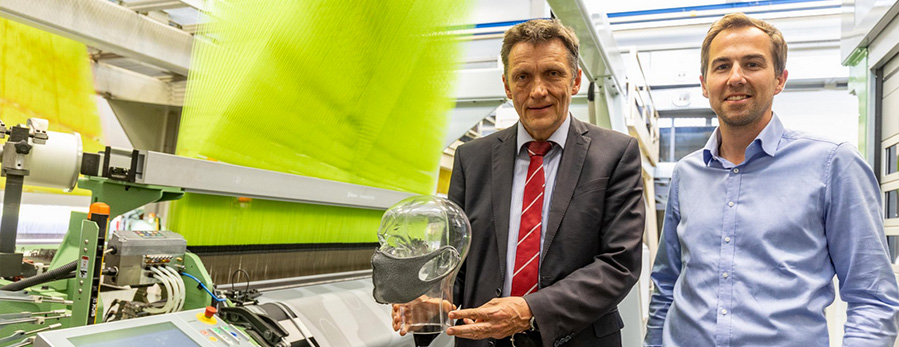

The project that has now been approved by the DITF under the direction of Dr. Hans Jürgen Bauder, head of the weaving technologies division at the DITF, addresses these requirements with a completely new manufacturing approach: while the common protective masks are made of non-woven fabric and thrown away after having been used only once, the Denkendorf researchers are focusing on "ready-to-wear" one-piece masks. These are made of high-performance precision fabric woven in Jacquard weaving technique and, in addition, create the prerequisite for multiple use in order to save waste and avoid delivery bottlenecks.

An innovative manufacturing concept is realised for flexibly adaptable masks with significantly improved wearing comfort and thus higher protective function. According to initial calculations, the manufacturing costs are 6-8 cents/mask and thus provide a realistic basis for mass production.

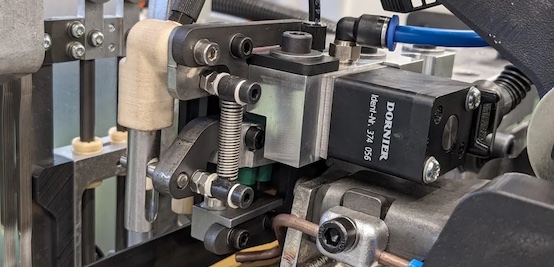

For this ambitioned project, DITF are using the latest technology from associated textile machine manufacturers and textile producers: Lindauer DORNIER is providing the necessary air-jet weaving machines, Stäubli AG is the project partner for the Jacquard weaving technology.

Global Safety Textiles has agreed to support the project regarding the complex warp beam production and the drawing-in of the warp threads. The company TWD Fibres supplies antimicrobial filament yarns and textured yarns for the prototypes and the start-up production. At the same time, split fibres from the DITF technical centers are used which favour an increased filtration efficiency and are almost as fine as the fibres for masks made of meltblown non-woven fabric.

The medical face masks do not have to be sterile, but must imperatively be low in germs (disinfected). A project partner is therefore also the cleaning company Textilpflege Mayer, which takes on this task and cooperates with the Ortenau Clinic in Offenburg to evaluate the masks. The testing of the masks according to the specifications of EN 14683 is carried out by the Hohenstein Test Institute.

The project focuses on the technical design of the woven face mask, which is to be made available for production to the 15 textile companies in Europe which operate a total of more than 200 Jacquard weaving machines. The production settings of the masks developed at the DITF can be immediately transferred to existing production facilities. This would enable the 15 weaving mills to jointly produce over 2 million masks per day at short notice – a significant contribution to further stabilising the supply situation for protective masks.