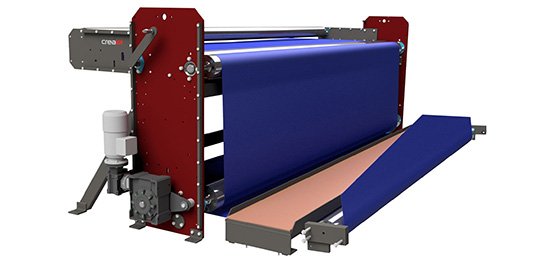

#Weaving

All Types of Creels

Wherever possible, overhead take-off creels can be used. However unrolling creels are used wherever a twist-free feeding of the yarns has to be guaranteed.

Each creel is built according to the customer’s specifications.

They can be specified for different yarns made out of:

- glass

- carbon

- metal

- basalt

The yarns are taken off from the creel and are passed through perforated plates with ceramic eyelets at the creel end. Then they pass an expansions comb before being fed via delivery unit to the weaving machine or the pultrusion unit.

The creel used must be able to accommodate the required number of bobbins and to ensure a constant tension over the entire thread sheet.

The feed unit controls the thread tension between the creel and the processing machines and supplies the yarns with the necessary tension to the manufacturing process.

The Crealet application expertise and industry know-how are the key to delivering solutions that meet the needs of their customers