#Research & Development

Borealis Innovation Award 2022 for the best HTL final papers

Measured in terms of value added, the manufacturing sector is the largest industry in Austria; its innovation potential, which is reflected in the approximately 1500 patents granted annually, is on a high level. An important factor contributing to this success are the graduates of the Austrian HTLs. Therefore, each year Borealis awards the best HTL final papers in the field of plastics and environmental technology at the TGM Vienna to promote young talent.

Modern technologies thanks to innovative solutions

While the automation of processes and the ongoing digital transformation ("digitalisation") play a major role in the public perception, modern technologies also require innovative materials. This is reflected in the final papers awarded this year, which dealt with topics such as process monitoring, processing optimisation, and flame-resistance of plastics in e-mobility.

Marie Dekan and Klara Hummer researched the use of artificial intelligence to monitor the quality of manufacturing processes in plastics manufacturing. This innovative approach was awarded with the first place by an expert jury.

The runners-up, Felix Petutschnig and Xaver Rossnagl, were honoured for their paper on the intrinsic reinforcement of polyethylene. Their research aims to facilitate the production of plastic components that have the same mechanical properties as steel.

Teodora Aleksic, Carina Bachmayer and Marko Cilek improved the safety of electric vehicles by developing a fireproof battery compartment, for which they achieved third place.

Addressing challenges together

The exceptional quality of the award-winning papers is reflected in the topicality of the subject matters, amongst other things. “The close link to current economic issues is what makes our HTL graduates’ final papers stand out,” Klemens Reitinger, head of the TGM department, explains. “It is thanks to the close relations between academia and industry that such projects can be carried out successfully and fully in line with current trends.”

This close cooperation is also reflected in Borealis' support for education programmes, and in the awards presented to students, honouring their academic achievements and innovation. Markus Horcher, Director Sustainability & Public Affairs at Borealis, put an emphasis on this fact during the award ceremony: “Our society’s path into the future is set by global, social and ecological challenges which can only be met with cutting-edge compound material solutions and technologies.”

Borealis sees the big challenges facing our society when dealing with the consequences of climate change, and at the same time meeting the increasing resource requirements of a growing global population. Horcher adds: “In line with these trends, we at Borealis are focusing on the comprehensive expansion of a sustainable circular economy, as well as on delivering innovations to achieve climate neutrality. To succeed in finding the right solutions to these challenges, we require young technicians with high commitment; this is why Borealis makes it a priority to support them.”

The commitment to a close cooperation between the TGM and the Austrian plastics industry was further illustrated by the large number of participants. Almost 150 representatives from commerce and industry attended the award ceremony in the ballroom of the Austrian Trade Association at the Palais Eschenbach.

Award Winners of the Borealis Innovation Award 2022

Winners

Topic: Process capability analysis through artificial intelligence

Project team: Marie Dekan and Klara Hummer

Partner company: Gabriel-Chemie GmbH

Summary:

In industrial production, the quality inspection of products often takes place at a later stage than the manufacturing process itself. If defective parts are discovered during these checks, a large number of products often have to be discarded. This problem could be remedied by an artificial intelligence (AI)-based system that is able to predict the quality of products in real time based on production parameters.

In their paper, Marie Dekan and Klara Hummer investigated the suitability of so-called neural networks for describing production processes in plastics technology. Their results showed that these AI models can identify important influencing variables and thus help reduce the reject rate.

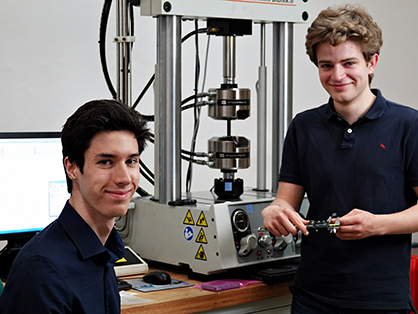

Runners-up

Topic: Self-reinforcement in polyethylene through shish-kebab structures

Project team: Felix Petutschnig and Xaver Rossnagl

Partner company: Laboratory for Plastics Technology Ges. m.b.H.

Summary:

High-strength components made of plastics seem rather unusual to many people, as plastic is commonly associated with products that are not very robust. This makes it all the more surprising that Felix Petutschnig's and Xaver Rossnagl's made it their goal to produce high-strength plastic products that can compete with steel.

For this purpose, a standard plastic (polyethylene) exhibiting distinct crystal structures due to a special processing method, using high pressure and orientation, was chosen. These structures, which are called “shish-kebab” because of their appearance, produce extraordinarily good mechanical properties.

Initial results have already been promising. By modifying the molecular lengths, the team was able triple material strength. With their work, the two plastics engineers hope to pave the way for the production of lighter yet stronger components in the future.

3rd place

Topic: Flame-retardant lightweight structures for battery compartments

Project team: Teodora Aleksic, Carina Bachmayer, Marko Cilek

Partner company: State Research Institute for Mechanical Engineering

Summary:

While electric mobility has seen a major upswing for some years now, fire incidents involving battery systems regularly show the potential hazards of this technology. Electric motorbikes from MotoE, for example, caught fire several times while charging the lithium batteries; similarly, vehicle fires at several well-known car manufacturers have also triggered a discussion about the safety of electric vehicles.

For this reason, Teodora Aleksic, Carina Bachmayer and Marko Cilek designed a flame-retardant battery compartment that is particularly light and intended for racing. The specially developed plastics and the lightweight components produced using 3D printing ensure low mass, while still delivering a high load-bearing capacity. The result is an energy-efficient battery compartment with enhanced fire resistance, which is already being tested in racing.