#Textile chemistry

“Best CO2 Utilisation 2021”: The three winners of the innovation award are turning CO2 into methanol, cleaners, plastic packaging or surfactants

More than 180 participants from 24 countries followed the 41 speakers online. Experts from industry and science presented their latest technologies and strategies and the most recent developments in science, industry and policy for Carbon Capture & Utilisation (CCU). The participants enjoyed excellent presentations, lively online discussions and interactive networking possibilities via video and text chat at the 9th Conference on CO2-based Fuels and Chemicals (http://www.co2-chemistry.eu), which included the 2nd European Summit on CO2-based Aviation Fuels. The conference proceedings will be available shortly at http://www.renewable-carbon.eu/publications.

Professionals from the fuels sector are expecting a high demand for sustainable aviation fuels (SAF). Worldwide, concrete quotas for SAF are about to be implemented, in some cases even sub-quotas for CO2-based SAF. And this not only in Europe, as speakers from Brazil and South Africa showed. The first large-scale plants are expected within the next five years. It seems that the SAF market will become the first mass market for Power-to-X.

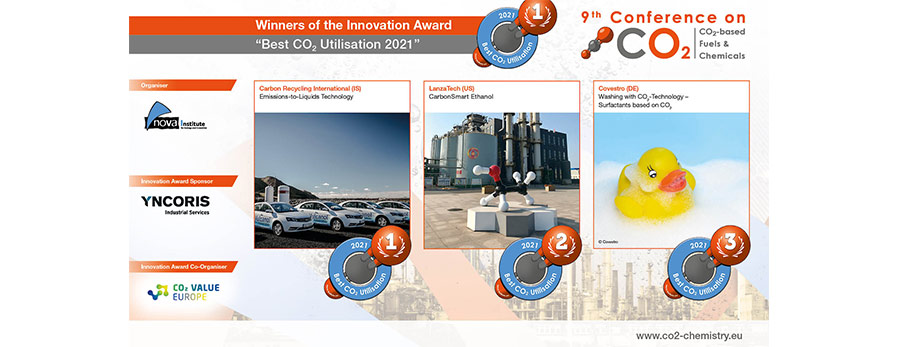

Best CO2 Utilisation 2021

One of the conference highlights was the competition for the innovation award "Best CO2 Utilisation 2021". The six nominated companies demonstrated their new technologies and products in short presentations. Afterwards, the three winners were elected online by the participants of the 9th Conference on CO2-based Fuels and Chemicals.

The innovation award was sponsored by YNCORIS (Germany), service partner for a future-proof chemical industry, and organised by nova-Institute (Germany) and CO2 Value Europe (Brussels), the only association exclusively dedicated to Carbon Capture and Utilisation (CCU).

The innovation award "Best CO2 Utilisation 2021" went to Carbon Recycling International (CRI) from Iceland, a pioneer for methanol production from CO2 emissions, now scaling up in China and world-wide. "Methanol is a highly versatile chemical building block and fuel and the CRI CO2 utilisation process now enables large scale utilisation, transport and storage of green or stranded energy. Increasingly, policy makers, investors and industry leaders are recognising that this is one of the key pieces we need, to solve the climate puzzle. We thank the organisers and sponsors for this great recognition.", says Ingolfur Gudmundsson from CRI.

The second winner is LanzaTech from USA. LanzaTech produces ethanol from the emissions of steel plants by using microorganisms. The renewable ethanol is used for fuels, and increasingly for every day products, such as cleaners and plastic packaging. "If we are to achieve our climate goals, we need a systems-level view and solutions that can draw on multiple sources of waste carbon, which these awards rightly highlight", states Babette Pettersen from LanzaTech. She envisions "a world where carbon is no longer a liability but an opportunity for all."

The third winner is Covestro from Germany, frontrunner of the CO2-based chemistry. After mattress foam and textile fibres made from CO2, Covestro now presented the first surfactants made from CO2 with good washing and biodegradation properties.

Martin Lindmeyer from YNCORIS is happy to "support these innovations and to provide a platform for promising new concepts. The challenges of transferring such technologies to industrial scale are manifold. They can only be mastered together."

These three innovators convinced the conference participants. They are the winners of the innovation award "Best CO2 Utilisation 2021":

First Place

Carbon Recycling International (Iceland): Emissions-to-Liquids Technology

Carbon Recycling International (CRI) has been developing its Emissions-to-Liquids (ETL) technology since 2006. CRI's first industrial demonstration plant was commissioned in Iceland in 2012. It has a capacity of 4,000 tonnes methanol per year. ETL converts CO2 and hydrogen into methanol in a one-step reaction. In 2020 the company moved from industrial demonstration scale to full commercial scale with a project in Anyang, Henan province, China. The plant, which will have a capacity of 110,000 tonnes methanol per year, will be commissioned in 2021. This represents an important step for CO2 hydrogenation projects worldwide. The CO2-based methanol is used for gasoline blending, biodiesel esterification, fuel cell operation, waste-water denitrification and chemicals production.

More information: http://www.carbonrecycling.is

Second Place

LanzaTech (USA): CarbonSmart Ethanol

The CarbonSmart Ethanol technology allows to capture carbon dioxide and to creating value from waste; effectively turning pollution into products. LanzaTech uses microorganisms to make ethanol from the CO2 and CO emissions of industrial processes like steel, syngas from municipal solid waste, waste wood or waste plastics. Ethanol is a chemical building block that can be used to produce a broad range of everyday products from household cleaning products, plastic shampoo bottles, furniture and toys, to fine fragrances and sporting goods. With a commercial plant in China that has produced over 20,000 tonnes of ethanol and mitigated over 100,000 tonnes of CO2 since 2018, the technology is rapidly gaining traction in the market. The steel company ArcelorMittal (Luxembourg) licensed LanzaTech’s technology and is building the first European plant to convert steel off-gases into CarbonSmartTM Ethanol in Ghent (Belgium). The plant is estimated to have a capacity of 62,000 tonnes of ethanol per year and to mitigate over 350,000 tons of CO2 per year.

More information: http://www.lanzatech.com

Third Place

Covestro (Germany): Washing with CO2-Technology – Surfactants based on CO2

CO2 instead of petroleum – Covestro is pursuing new avenues for turning the waste gas into a useful raw material. The goal is to use CO2 as resource in as many applications as possible. And the next scope is here to come: Surfactants based on CO2. First application tests have shown that these CO2-based surfactants can be used in a standard detergent formulation. The product development process is still in progress and the boundary conditions are already set: less fossil-based, less global warming potential, readily biodegradable and comparable washing performance – a new class of more sustainable surfactants for the everyday businesses.

More information: http://www.covestro.de

Patronage, sponsors and partners

The nova-Institute would like to thank Professor Dr Andreas Pinkwart, Minister of Economic Affairs, Innovation, Digitalization and Energy of the State of North Rhine-Westphalia (Germany) for taking on the patronage of the conference.

Further, nova-Institute thanks YNCORIS (Germany) for sponsoring and CO2 Value Europe (Brussels) for co-organising the innovation award "Best CO2 Utilisation 2021". The 9th Conference on CO2-based Fuels and Chemicals is supported by Gold Sponsor VTT (Finland), Silver Sponsor Covestro (Germany) and Bronze Sponsor Axel Semrau (Germany). Further information on our attractive sponsoring packages can be found at

http://www.co2-chemistry.eu/sponsoring.

The nova-Institute also thanks its partner IASA e.V. (Germany) for supporting the conference.