#Textile chemistry

Toray to expand Toraysee™ cleaning cloth lineup with offering that enhances hygiene management at stores and salons

The company is bringing out the new offering to help salons, mobile phone sellers, opticians, and other shops offering in-store service to safeguard the health of staff and customers from COVID-19. It has become routine at such establishments since the pandemic began to have people disinfect their hands to prevent contact infections, install partitions to safeguard from airborne droplets, and remove pathogens from objects.

While frequently wiping tables, chairs, counters, and other surfaces as part of disinfection and sterilization efforts is also important, stores and salons frequently find this procedure very labor-intensive. Toraysee for Shops and Salons overcomes that challenge because it wipes faster and more effectively than regular cleaning cloths. Toray research found that the cloth can remove 98% of stains when it is dry and 99% when it is wet. The cloth is also economical because it can be washed and reused without compromising performance. The fabric employs a special, quick-drying weave.

Toray debuted the Toraysee brand in 1987 as an advanced cloth for wiping eyewear. The company has since expanded the range to include numerous popular cleaning products. It will continue to develop high-value-added merchandise for the Toraysee series in the years ahead.

Overview

Exceptional cleaning effectiveness

Applications: Oil stains, water stains, splashes, sebum, fingerprints, dust, tape marks, etc.

(1) Fibers that are just 4 to 6 microns in diameter, or about 1/250th the diameter of a human hair, use their micro-pockets to draw in and remove even the smallest stains during wiping

(2) The cloth can be used dry or with water or disinfectant

(3) After wiping, water droplets are very fine and dry fast without a trace

(4) Washing restores performance with this durable item

(5) The cloth incorporates MAKSPEC, an antibacterial fiber that inhibits the growth of staphylococcus aureus and pneumoniae bacteria, keeping it clean and safe

2. Outstanding efficiency

(1) Removes stains cleanly with or without detergents

(2) Can be used with appropriate concentrations of alcohol and sodium hypochlorite disinfectants owing to its outstanding chemical resistance

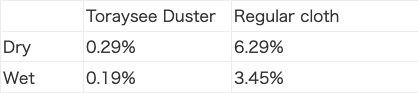

(3) Micro pockets draw dirt in, so reapplication of contaminants to surfaces is just 1/20th that of ordinary cloths

(4) The cloth dries around three times faster than normal ones so it can be reused during business hours and daily cleanups.

Reapplication from cloth

Stain transfer rate

Fabric dryness

Toraysee for Shops and Salons dries in just over an hour, compared with more than three hours for regular cloths

Cloth drying rate

Toraysee

Regular cloth

Source: Toray research

Toraysee Store and Salon Cloth Data Sheet