#Techtextil 2024

Period underwear made from biobased materials at Techtextil

On average, a woman consumes about 15,000 hygiene products in her lifetime, primarily disposable items that generate significant waste. Their plastic components take up to 500 years to decompose, breaking down into smaller and smaller pieces over time. The trend toward making female hygiene products, both disposable and reusable, more sustainable has been growing in recent years. This category includes not only biodegradable disposables but also washable period panties offered by established lingerie manufacturers and innovative startups.

Enhancing sustainability and performance of reusable products

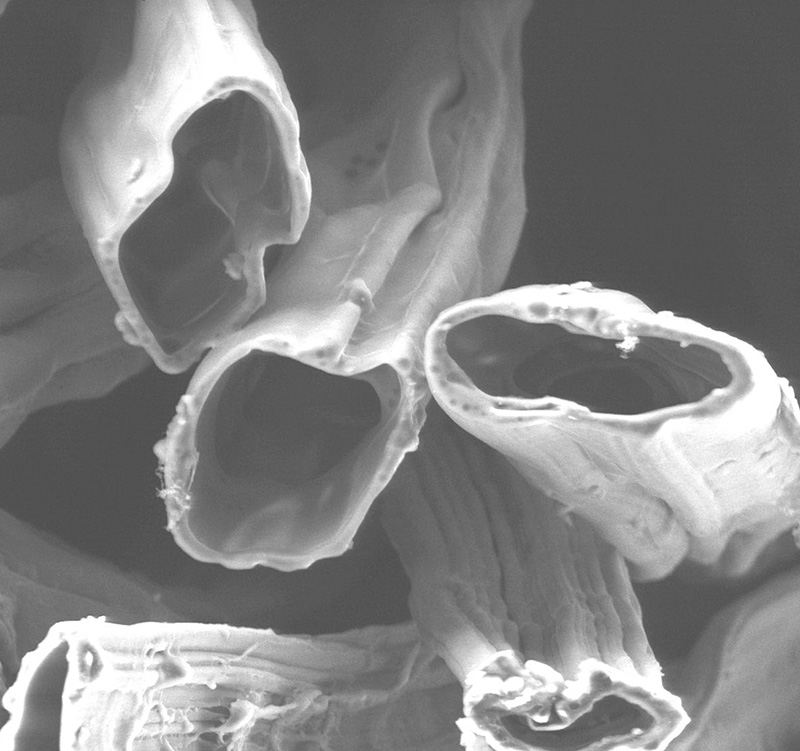

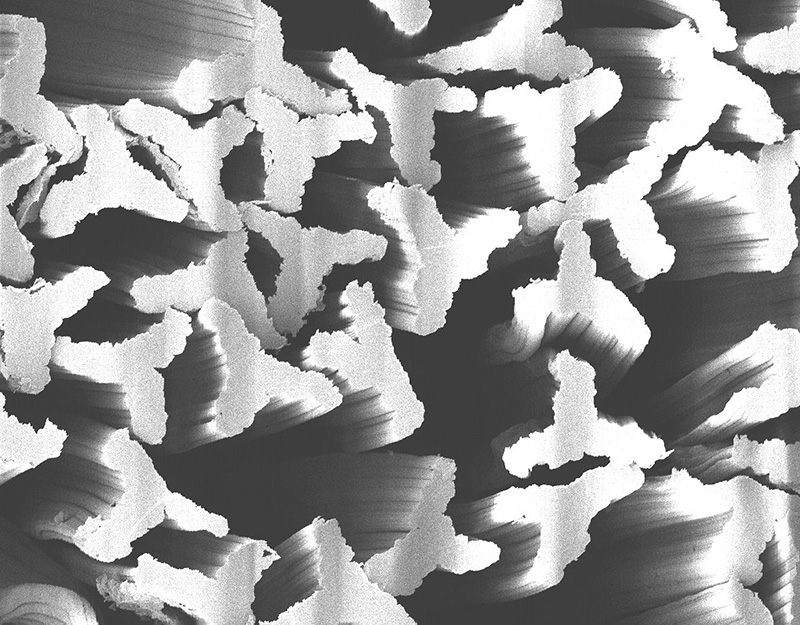

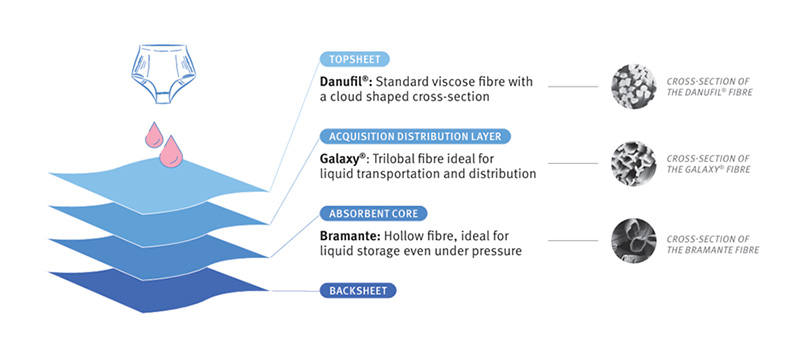

This is where fibre manufacturer Kelheim Fibres and yarn spinner Gebr. Otto step in, aiming to make period underwear as comfortable, high-performing, and sustainable as possible. The solution is akin to solving a puzzle, considering that period underwear is constructed from multiple layers with different functions. For instance, the topsheet must quickly absorb and divert liquid away from the body, while the subsequent acquisition-distribution layer (ADL) ensures rapid and optimal distribution of the liquid within the absorbent core, which then encapsulates the liquid, preventing potential leakage.

Pooling expertise

With the optimal combination of Kelheim’s specialty fibres and Otto’s perfectly matched yarn types, the two innovation partners have solved this puzzle. The result is a prototype that outperforms conventional solutions in terms of liquid absorption speed, capacity, and rewet values. “Based on the requirements and test results Kelheim has determined for the various layers, we develop our yarn blends,” explains Andreas Merkel, Managing Director of Gebr. Otto. “We can promptly supply the desired yarns for short-term requests, including special inquiries from lingerie brands.”

Inherently sustainable

The collaborative innovation between Kelheim Fibres and Gebr. Otto is a significant gain for the sustainability of period underwear. Not only do both companies utilize efficient state-of-the-art technology, but Kelheim’s biobased viscose fibres also contribute to the eco-friendliness of the product. Moreover, the partnership between these two German traditional companies enables an exceptionally short supply chain. Dr. Marina Crnoja-Cosic, Director of New Business Development at Kelheim Fibres, emphasizes: “Short supply chains are not only environmentally friendly but also crucial for compliance with supply chain laws and product responsibility. Regional partnerships like the one with Gebr. Otto ensure that our supply chain is transparent and efficient, ultimately leading to a more sustainable future.”