#Techtextil 2022

Techtextil Innovation Award 2022 goes to ITM for novel textile heart valve prostheses developed

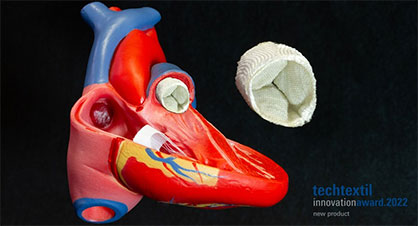

Within the framework of a research project of the Industrial Joint Research (IGF), scientists of the ITM developed novel textile heart valve prostheses. The implants can be precisely adapted to the anatomical shape and placed in the heart in a minimally invasive way. The textile heart valve is integrally manufactured. Here, the valve is integrated in situ during the weaving process. Thus, the flow-optimized heart valve consists of a single textile structure. Further joining processes, e.g. by sewing, are no longer required. This reduces the manufacturing effort enormously in contrast to today's production of biological heart valve prostheses by hand.

Prof. Chokri Cherif, Institute Director of ITM, and his team are very pleased about the continuous interdisciplinary research successes that are constantly achieved at ITM in close cooperation with technical weavers, medical experts and users. "Already two years ago, we were honored with this novel development as one of the three finalist teams of the Otto von Guericke Prize 2020. The selection for the Techtextil Innovation Award 2022 is a renewed confirmation of the need for our practice-oriented research and a special tribute, but at the same time also a further incentive for the prompt implementation of our research results in industry."

To date, mechanical and biological valves have been available for the treatment of defective heart valves. The novel woven heart valve prostheses are expected to combine the advantages of both types: unlimited lifespan, no need to take blood-thinning drugs for life, and minimally invasive surgery. Furthermore, the textile heart valves can be manufactured in a time- and cost-saving manner with high reproducibility and quality.

To date, mechanical and biological valves have been available for the treatment of defective heart valves. The novel woven heart valve prostheses are expected to combine the advantages of both types: unlimited lifespan, no need to take blood-thinning drugs for life, and minimally invasive surgery. Furthermore, the textile heart valves can be manufactured in a time- and cost-saving manner with high reproducibility and quality.

video presentation of the awarded project can be found under this link.