#Spinning

Rieter reports stable order backlog and strategic progress – outlook for 2025 adjusted

The market situation continues to be characterized by investment restraint due to trade policy uncertainty in key markets. Although Rieter registered growing interest for new machine projects, many requests did not yet lead to binding order intake as customers postponed their investment decisions until the 2026 financial year. Lower volumes in the machinery business and the associated weaker demand for installation services, along with cost-saving measures by customers, are delaying the conversion of orders into sales and are also weighing on the earnings of the After Sales and Components Divisions.

Order intake

In this challenging market environment, Rieter’s order intake totaled CHF 559.3 million in the first nine months of 2025 (2024: CHF 629.8 million). Adjusted for major orders from the customer DIW (China) in the 2024 financial year, order intake increased by 11% in the first nine months. The increase was driven by a strong third quarter in 2025.

The order intake of the Machines & Systems Division fell to CHF 287.1 million, representing a decrease of 17% compared with the first nine months of the previous year. The Components Division recorded a year-on-year decline of 13% to CHF 142.6 million. At CHF 129.6 million, order intake in the After Sales Division was up by an encouraging 9%.

Sales

Converting the order backlog into sales remained challenging due to the ongoing geopolitical uncertainties. Longer book-to-bill cycles can be observed in the after-sales business in particular.

In the first nine months of 2025, Rieter generated cumulative sales of CHF 457.7 million (2024: CHF 584.3 million), representing a decrease of 22% compared with the same period last year. Sales in the third quarter of 2025 amounted to CHF 121.5 million (Q3 2024: CHF 163.3 million). The Machines & Systems Division generated sales of CHF 191.9 million in the first nine months of 2025, a decline of 27% compared with the same period last year. Sales in the Components Division amounted to CHF 154.6 million, down 16% on the previous year’s period. The After Sales Division recorded an 18% decrease in sales to CHF 111.2 million in the first nine months of 2025.

Order backlog

As of September 30, 2025, Rieter’s order backlog was around CHF 590 million (September 30, 2024: CHF 690 million).

Significant progress in strategy implementation

The Rieter Group has made significant progress in the implementation of its strategy. This is the result of the strengthened technology leadership in automation and digitization, the consistent implementation of the performance program and the planned acquisition of the Barmag Division.

Automation and digitization

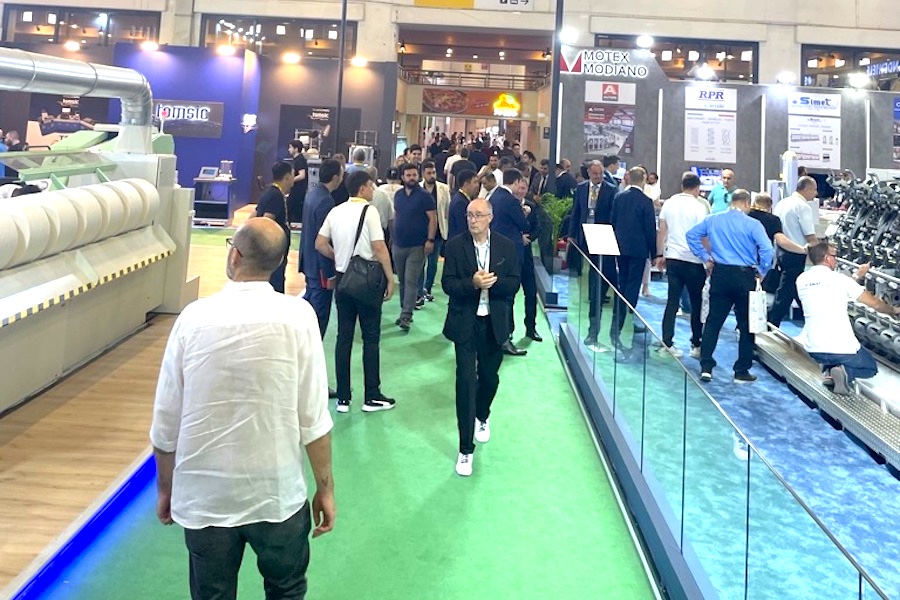

Since acquiring the winding machine business in financial year 2021, Rieter is the only systems provider that covers the complete manufacturing process from fiber preparation through to the four end-spinning technologies. At ITMA 2027 in Hanover (Germany), Rieter will present a fully automated spinning mill that achieves maximum efficiency with minimum personnel costs. At ITMA ASIA + CITME in Singapore in October 2025, Rieter will present new automation solutions that support fully automated production.

Performance program

Rieter is consistently implementing the measures of the performance program. This includes strengthening the most important sales markets, optimizing the supply chain and consistently managing overhead resources. Since the introduction of the performance program in financial year 2023, overhead costs have been reduced by more than CHF 100 million.

Barmag acquisition

The planned strategic acquisition of the Barmag Division gives rise to a globally leading systems provider of natural and man-made fibers. Rieter is confident that all required regulatory approvals for the completion of the acquisition will be obtained in the fourth quarter of 2025. This step represents an important milestone in the implementation of the company strategy which was announced in October 2024.

Outlook for the full year 2025 adjusted

As a number of projects have been postponed for delivery in 2026 due to macropolitical uncertainties, Rieter (without consideration of the Barmag Division) now expects sales for the full financial year 2025 of around CHF 700 million (previously: CHF 750 to 800 million).

Despite lower sales volumes, Rieter still expects an operating EBIT margin at the lower end of the range of 0% to 4% (excluding restructuring costs and costs associated with the acquisition of Barmag).

For the full year 2025, Rieter expects:

+++ Transaction costs with an impact on EBIT of around CHF 15 million.

+++ Significant additional restructuring costs with an impact on EBIT.

+++ Net financial expenses, including the expenses associated with the acquisition of Barmag, of around CHF 20 million.

As a consequence, Rieter’s 2025 net result is expected to be negative and thus deviate significantly from the prior-year figure.