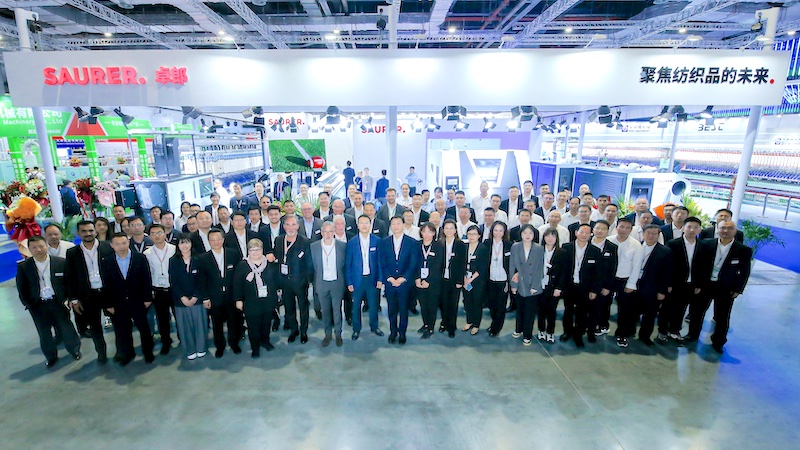

#ITMA Asia + CITME 2024

Successful at ITMA Asia 2024 - Saurer's technology highlights

The Autocard SC 8, exhibited for the first time, impressed the visitors with its innovative features and carding area of 4.8m2. The latest generation of air spinning technology, the Autoairo, and the Autocoro 11 - the fully automated rotor spinning machine, were always surrounded by interested visitors. The energy-saving and robust Zinser 51 ring spinning machine produced Siro Compact yarn on the booth, while the PrimeTwister impressed many textile professionals with its flexibility and performance.

Saurer's spinning and twisting solutions incorporate leading technology for the yarns of tomorrow and offer high flexibility to respond to the changing demands of the yarn market.

Recycled fibres: All Saurer machines can be configured to process recycled fibres and their blends, which will be in high demand in the future. Saurer machines are developed with a focus on high fibre utilisation to avoid waste during the pre-spinning and spinning process.

Flexibility in yarn production: low pilling yarns, fancy yarns, core yarns, compact yarns, siro compact yarns, high quality twists or sophisticated carpet yarns, and much more.

Saurer yarn brands: To ease marketing, we created yarn brands to be used for free for our customers: Belcoro – for rotor yarns spun on Autocoro, Belleo – for rotor yarns produced on BD machines and Belairo – for yarns supplied from Autoairo air spinning machines.

Fabric samples made from Saurer yarns: The touch and feel of recycled yarns produced is important for the end user and fashion industry. At ITMA, Saurer exhibited various end products, such as shirts, T-shirts and hoodies, all made from yarn supplied by Saurer customers.

Autocard SC 8 – digitalised and monitored high-performance card: With a modern design and the industry’s largest carding section of 4.8 m2, the SC 8 delivers superior fibre utilisation and improved carding uniformity. The machine is equipped with automated settings and smart monitoring, including temperature monitoring for the carding gap, ensuring constant sliver quality. The SC 8 is particularly efficient when processing recycled fibres, providing higher material utilisation rates and improved production efficiency.

Zinser 51 – robust, flexible and energy saving ring spinning machine: The Zinser 51 ring spinning machine demonstrated Siro Compact yarn production and highest speeds during ITMA Asia and attracted a lot of visitors. With a robust design and energy saving features, the Zinser 51 offers easy operation and consistent yarn quality, even with 2056 spindles. Its energy-efficient suction system and flexible automation solutions make it an ideal choice for mills producing high-quality ring or compact yarns or processing recycled fibres.

Autoairo – air spinning for cotton and blends: Known for outstanding high speeds and automation with individual drives, the Autoairo air spinning machine processes cotton and other fibres to yarns with low hairiness and textiles with low pilling. With its speed, compact design and low space consumption Autoairo offers an economical alternative to traditional spinning methods. At ITMA Asia, the Autoairo was spinning up to 500 m/min, showcasing its ability to produce high-quality yarns, named Belairo, ideal for knitted fabrics and towels. The flexibility in use was demonstrated by spinning combed cotton, carded cotton, PES and a cotton / viscose blend.

Autocoro 11 – leading technology in rotor spinning: The fully automated rotor spinning machine Autocoro 11 offers an additional 10% energy savings compared to its predecessor, the Autocoro 10. With the Recycling Xtreme version, Autocoro 11 has been optimized to process the shortest fibres, especially recycled materials and is equipped with advanced dirt-eliminating features. An innovative rotor cleaning technology ensures efficient waste removal during the processing of recycled fibres. High-quality Autocoro yarns are well appreciated in the market and branded as Belcoro yarns. The Autocoro 11 is available with 816 positions – impressive 103 m long.

BD 8 and BD 480 Plus – economic and ergonomic rotor spinning: The semi-automatic BD 8 rotor spinning machine is ideal for cost-effective recycling and waste spinning. The new Twinsuction system provides up to 10% energy savings, while Digital Joint Spinning In technology ensures a quick restart after power failures. Equipped with up to four automatic doffer units (DU), it offers high spinning efficiency. Key features include take-up speeds of up to 230 m/min, an LED operator guide, and ergonomic design. Belleo is the new brand name for top yarn quality as well as an efficient, sustainable production on the BD. The BD 480 Plus is available with 2 automatic doffer units (DU) for package change, allowing customers to benefit from increased efficiency and a reduction in manpower.

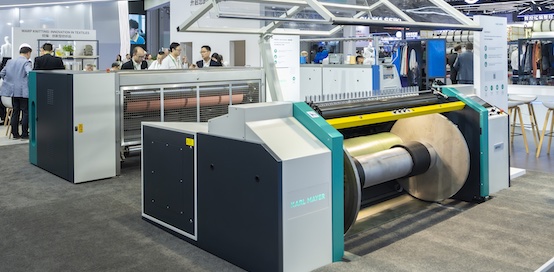

Texparts – high-quality components: Saurer’s Texparts product line provides premium components for the textile industry, including drafting systems, spindles, spinning rings, travellers, and bearings for ring and rotor spinning, winders, and twisters. Texparts components enhance yarn quality, productivity, and are energy-efficient at the same time. Using the new Eshape spindle with a reduced wharve diameter of 17.5 mm, combined with the Spinnfinity system, leads to up to 6% energy savings in ring spinning.

Sun – Service Unlimited – lasting a lifetime. Saurer offers tailored service solutions for its machines, ensuring a long and productive lifespan. Customers can upgrade machines with the latest technology to enhance productivity or for recycled fibre processing. These services help mills improve quality, performance, and profitability. The rX Recycling Xtreme Autocoro upgrades allow customers to benefit from the latest Saurer developments which can be implemented in older machine generations. Saurer's Customer Support experts were presenting a lot of solutions for the specific needs of each individual customer at the booth.

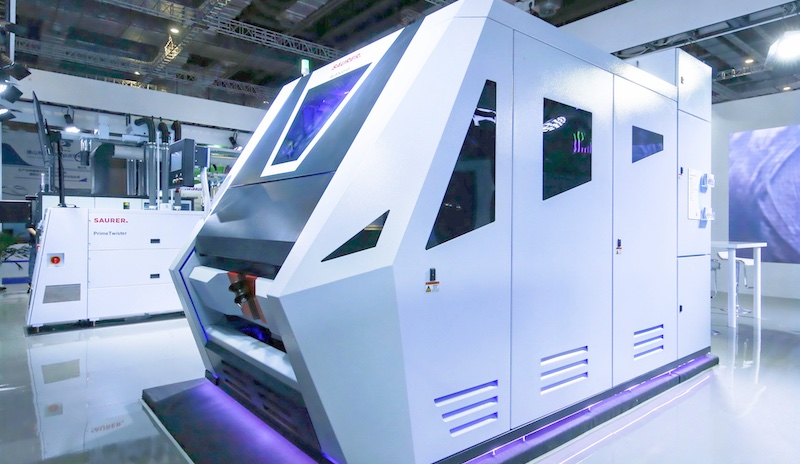

PrimeTwister – with exceptional flexibility: At ITMA Asia, Saurer showcased the PrimeTwister, a cutting-edge two-for-one twisting system for staple fibre yarns, including cotton, blends, and sewing threads. This latest model offers great flexibility across a wide range of yarn counts, making it ideal for diverse production needs.

The PrimeTwister reduces energy consumption by up to 40%, thanks to innovative spindle geometry and advanced bearings. High-quality yarn guides ensure consistently superior twist quality and sets new industry standards. Its compact design minimizes production space, cutting building and air-conditioning costs while streamlining operations. With low maintenance and service requirements, reduced assembly and installation times, the PrimeTwister is efficient, reliable, and offers an excellent return on investment for twist manufacturers.

Saurer's twisting systems offer exceptional variability and flexibility and the product range also includes the CompactTwister, an energy saving reliable two-for one twister, the CableCorder CC5 for processing tire cord, the TechnoCorder TC2 for industrial yarns as well as the CakeFormingWinder and GlassTwister for processing high quality glass filaments.

Fibrevision – synthetic yarn monitoring: With the increasing amount of recycled synthetic fibres defects occur more often and yarn monitoring and grading material is getting more and more important. Saurer provides advanced yarn quality monitoring systems to minimize waste and maximize quality in synthetic yarn production. Fibrevision’s Total Quality System (TQS®) covers various yarn types, from POY to DTY, using sensors that detect defects like broken filaments, interlace level, and yarn diameter variation. The systems ensure real-time quality assurance, with options for both online and offline monitoring.

Automation and digitalisation solutions: As labour shortages grow in Asia, Saurer’s automation technologies help mills streamline operations, increase output, and maintain consistent yarn quality. Saurer’s Senses digital data analysis tool enables customers to monitor and control their production processes, reacting swiftly to quality deviations and optimizing efficiency.