#Spinning

The 20-year success story of card clothing at Trützschler

The origin story

A giant leap in the card clothing technology is marked in the 1950s. At that time, Germany 's Black Forest region was a hotspot for producing textiles and attracted companies around the world - one of it was the American textile machinery producer Hollingsworth. After filing for bankruptcy in 1996, it narrowed its portfolio to focus on card clothing. The company also placed a stronger emphasis on modernizing and automating its facilities.

Bold decision, big challenges

The card clothing business in the Black Forest made impressive advances. In 2003, Trützschler took the bold decision to acquire the company and step into the card clothing market. This led to the creation of Trützschler Card Clothing (TCC). It led to some big challenges too.

First, Trützschler needed to optimize the card clothings produced in Neubulach-Oberhaugstett to fit its carding machines – and it needed to do it quickly. That involved detailed evaluations and trouble-shooting exercises. On top of this, each new generation of card clothing brought additional challenges that required the Trützschler team to adjust its products and processes.

Thanks to close cooperation between colleagues from the Spinning, Nonwovens and Card Clothing teams at Trützschler, they now offer a uniquely comprehensive card clothing portfolio with support from their deep expertise in this area. This valuable competitive advantage helped Trützschler take over the American part of Hollingsworth in 2010, which is now integrated into American Trützschler in Charlotte.

Twists, turns and technology leadership

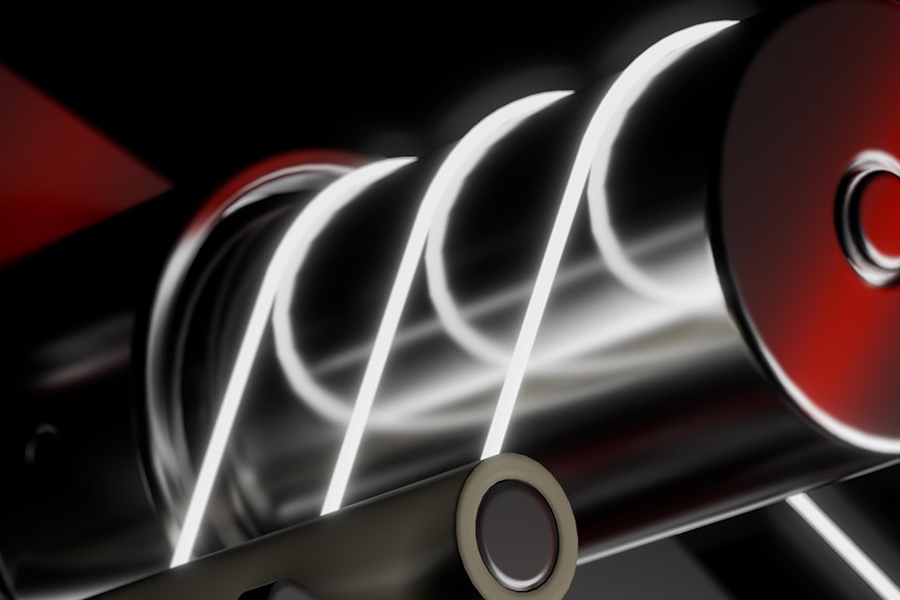

Huge changes have happened since Trützschler entered the card clothing industry 20 years ago. Magnet systems for the flat top of the card are one very special milestone for card clothing technology. These Magnotop (MT) systems enable faster and simpler servicing during production, as well as significant savings in operating costs. The different wire geometries of GX and FGX are further examples of big progress. The team also developed the self-adjusting flat top, Precisetop (PT), which enables continuous carding gaps that are thinner than a sheet of paper.

Major technological developments like these are the result of close collaboration and interaction between departments at Trützschler Group for two decades. That team spirit and passion for shared success have made the company a global technology leader in the card clothing business today.

Growing and going global

From its starting point in the Black Forest, TCC has expanded worldwide at impressive speed. The company now offers production sites, sales teams and service experts close to its customers around the globe. Importantly, the production facility in Neubulach-Oberhaugstett has also experienced remarkable growth. The site is now larger and features a broader range of production processes, with significant efficiency improvements. This growth of TCC and the high demand for its wires has empowered the card clothing business to rapidly increase its production volume in the last 20 years.

Highly engaged and talented people are the key to this success story. More than 150 employees now work at the TCC headquarters in Neubulach-Oberhaugstett, with more than 350 people serving customers as part of its global team. Looking ahead, TCC is still taking steps to carry this expansion into the future. The ongoing construction of a new logistics center is just one flagship project. At all times, TCC teams are continuously improving the production processes at its growing network of sites to maximize efficiency while minimizing the environmental footprint.

A never-ending story...

The development of TCC may only stretch back for two decades, but it’s a tale packed with big moments and exciting plot points. Since it joined Trützschler Group in 2003, TCC has benefitted from its parent company’s distribution channels and OEM equipment. In the same spirit, the Trützschler Group has enjoyed positive progress overall as a direct result of the two-decade success story of TCC.

Today, TCC has a powerful reputation for leading technological advances and setting new standards in the card clothing market with its inspiring R&D activities and truly global market perspective. In just 20 years, the business has developed a comprehensive range of products and services that are trusted around the world. And its global team of passionate people is excited to continue this story for many years into the future.