#Spinning

Hidden secrets, open success

Practical cases and established success stories are always valuable in the nonwovens business: everybody wants to know the secrets of success. How do some companies achieve outstanding product quality standards and maintain a highly profitable business? Of course, this info is private and jealously guarded by the companies, as well as by the Uster experts who share their confidences.

Contamination control, part one

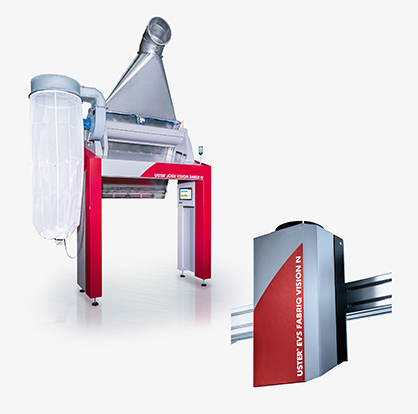

What Uster will do, however, is provide the key for companies to unlock these secrets for themselves. Basically, it’s the perfect combination of top technology and world-class application knowledge. Powerful imaging spectroscopes in the Uster contamination sorter will detect and eject any particle that differs even slightly in color from the main fiber. Nothing can hide: contamination in cotton or synthetic fibers can be reliably identified down to a size of one square millimeter. And here we open another secret of success: the Uster Jossi Vision Shield N is ideally located directly after the fine opener, exactly the point where contamination can’t hide from the spectroscopes.

Many nonwovens producers are now seeing the growing business potential in recycled fibers. Profit margins look fine, but getting the quality right is not easy. “It is a proven fact that recycled fibers are still today prone to infinite and inconsistent quality variations. Operating a high-performance contamination sorter in the production line is the best way to ensure an acceptable end-product,” says Mario Siegenthaler, Product Manager Fiber Cleaning at Uster Technologies.

Uster Jossi Vision Shield N can detect defects from any light pastel, grayish or brownish base material. “We use our know-how and expertise to further develop technologies in the ‘invisible’ range of IR and UV light for our imaging spectroscopes,” says Siegenthaler.

Contamination control, part two

Uster solutions have a two-way approach to superior quality control. Uster EVS Fabriq Vision N comes at the end of the production sequence, for automated detection of all the main defects arising from the process – and any remaining contamination. Even at full line speeds, Uster guarantees reliably high levels of fault detection for nonwovens manufacturers. Fabrics are automatically inspected and graded. It’s total control, preventing any defects in manufacturing from reaching the end-product.

The most common defects include unopened fibers, neps, black spots, holes and other issues, all of which are reliably detected by the Uster systems. They prevent raw material losses, second quality production, or – worst of all – customer claims. “Uster EVS Fabriq Vision N ensures reliable fault detection by using automated inspection during the production process – and significantly reduces the risk of customer claims. The system’s ability to capture any visible faults also allows web yield to be optimized,” says Michelle Salg, Product Manager Fabric Inspection at Uster Technologies.

Opening secrets

Uster’s automated quality monitoring solutions are also attracting interest from the nonwovens machinery manufacturers. “We are proud to say that completed projects show that the Uster Jossi Vision Shield N has a relevant impact on major business goals and influences key performance indicators positively,” says Siegenthaler. “With our reputation for attention to detail, nonwovens companies are eager to raise their issues for discussion.”

Nonwovens companies regularly call at Uster exhibition booths to leave samples for testing – or send them in later. “We consider this as a sign of trust. And of course, we like to help and use our expertise to give advises,” says Siegenthaler.

The producers also appreciate the detailed advice of Uster experts on obtaining greatest business value from their investment, by ideally integrating its systems into their production and processing environment. It is this perfect balance between open collaboration within the mill and total confidentiality outside that makes Uster a reliable partner for the nonwovens industry.