#Spinning

Drawing fibers to perfection

Godet rolls made in Switzerland meet topmost expectations

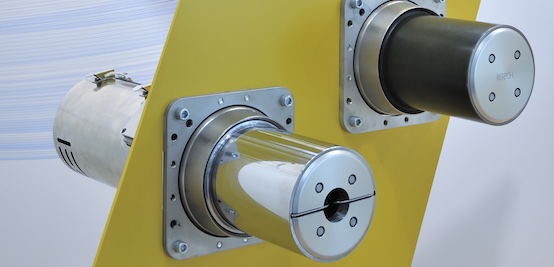

These threads – some literally life-saving – are made of polyamide, polyester, polypropylene, aramid, carbon, bio-based and many other polymers, categorized as technical yarns and high-performance fibers. Retech is the expert, backed by over 45 years of experience, in heat treatment and drawing man-made fibers of any material. The Swiss company launched two innovative godet rolls lately: the Ø 250 mm model developed for technical yarns and the Ø 320 mm model, reaching out to today’s temperature conditions, as needed for high-performance fibers such as aramid.

High-tech for a secretive business

Yarn engineering is a secretive business when it comes to sensitive applications, as well as future developments. Customers build on Retech expertise and trust its wide range of key components in perfectly meeting requirements such as temperature, speed and torque. But only in rare cases does the customer provide any information about the yarn and its final characteristics. “Comparing required customized solutions shows us trends regarding the market demand for godet rolls. It becomes our ambition to innovate the one godet roll meeting these latest customer needs,” says Ralph von Arx, CEO, Retech AG.

Identifying a strong demand for technical yarns with maximum strength, Retech addressed this with the newly-launched type Ø 250 mm roll, with an ideal length of 420 mm to process eight or twelve threads at a time. The extended diameter of 250 mm allows a significantly higher speed with the same dwell time. Additionally, the higher motor torque guarantees the very best results in yarn tenacity.

Further technical parameters are as remarkable: speed can be ramped up to 6500 m/min – applying a torque value of 15 Nm through the full speed range – and the temperature reaches 250°C with an excellent temperature profile of +/- 1.5 °C over the whole working width of the godet roll. When comparing its performance with the popular type of Ø 220 series, the achievements become even more impressive, since the speed can be increased further, as well as the torque. These differences make it possible to process a much wider range of yarn counts.

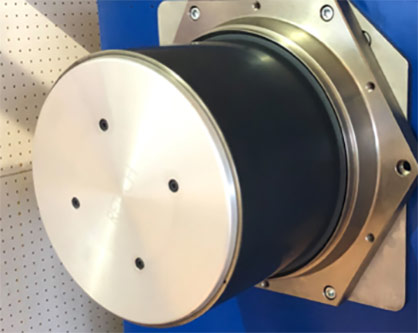

Reaching to the limits of strength boundaries

Retech has built a strong reputation for using technology enable a larger diameter and the required heating capacity within limited space. Results have been excellent, and successful projects also tend to lift expectations even further. “We continuously touch today’s technical limits and stretch to tomorrow’s possibilities when developing. We take the risk, and try to optimize at the edge,” says von Arx. The new type Ø 320 mm, specially developed for high-performance fibers, has become Retech’s latest pride, and evidence of its efforts to support today’s yarn engineering ideas.

Featuring various length, this type is ideal for serpentine yarn paths to multi-enlacement, and suits practically all machine concepts and yarn paths. For high-performance fibers it’s essential to optimize heat entry into the yarn, so the first step must be to extend the dwell time, which in turn is influenced by speed and diameter. The top diameter of Ø 320 mm allows the number of revolutions per minute to be reduced, resulting in optimum dwell time – while taking the advantage of an enlarged contact area. Unique yarn characteristics are made possible by impressive temperatures up to 400 °C, along with torque values of 35 Nm and speeds up to 1500 m/min.

Aramids are today the strongest textile fibers. Para-aramids generally have high glass transition temperatures nearing 370 °C. Heat treatment under tension increases crystalline orientation for unique tension values – all perfected when mechanical drawing orients the polymer chains in the fiber direction. For two reasons, the Ø 320 mm model is the ideal godet to produce sophisticated products such as aramids: it meets technical requirements for heat, torque and speed and it performs at the required precision. Retech’s reliability in use is founded on precise temperature measurements and adjustments – a major aspect of continuous developments.

Until the ultimate

Committed to constant innovation and improvement, Retech engineers have already worked on perfecting the new generation of temperature transmitters successful launched at ITMA 2019. Changes in the temperature control of the individual induction heater zones have improved power input and load distribution. More uniform power input into the inductor reduces the pulsation of the induction heat and prolongs the lifetime of the induction heater itself, as well as of the motor bearings. The smooth-running high-precision drives become even smoother, which brings significant advantages. For example monofilament, producers are able to make yarn of finest titer without the slightest variation in diameter. Last but not least, the changes additionally have a positive effect on the power grid, making its utilization more even, with fewer peaks, and facilitating a more balanced running of the mill’s system load.

The culture of ongoing enhancement and the desire for perfection make Retech a reliable partner when it comes to yarns for challenging – and especially life-saving – applications. “Producers can rely on us. We never stop until we can draw our customer’s fibers to perfection,” says von Arx.