#Nonwovens / Technical Textiles

ANDRITZ to deliver new high-speed spunlace line to Chuzhou Jinchun Non-woven Fabric, China

The line will produce lightweight fabrics for the hygiene industry from 30 to 80 gsm with a capacity of up to 17,000 tons per year. Start-up is scheduled for the first quarter of 2014.

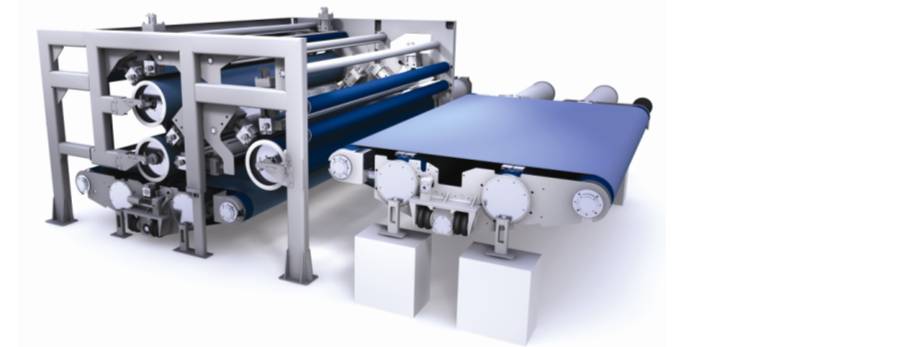

The scope of supply includes a Jetlace 3000 hydroentanglement unit, dewatering system, and a Perfodry Avantage dryer – all in-house technologies of ANDRITZ Nonwoven. The high quality and capacity of the line as well as the expected reduction in energy consumption were decisive for the award of this order, which once again confirms the position of ANDRITZ as one of the leading suppliers of spunlace technology for the Chinese market.

Chuzhou Jinchun Non-woven Fabric is one of the leading Chinese nonwovens producers. The company produces spunlace rolls for hygiene or wipes fabrics, synthetic leather or filtration applications. After start-up of this new line, Chuzhou Jinchun Non-woven Fabric will have a total spunlace capacity of 32,000 tons per year.

Pic: Signing of the contract during the ShanghaiTex exhibition. Front row (from right to left): Mr. Cao Songting, Executive Director of Chuzhou Jinchun Non-woven Fabric; Mr. Rakesh Kumar, Managing Director of ANDRITZ Wuxi, and Mr. Frédéric Noëlle, R&D Manager of ANDRITZ Perfojet; back row (from right to left): Mr. Gao Huaizhong, Secretary of Chuzhou Langya District Committee of the Chinese Communist Party; Mr. Wang Tu Qiang, Vice Mayor of the People’s Government of Chuzhou.