#Technical Textiles

Cinte Techtextil China proves to be dynamic international platform and launchpad for new market potential

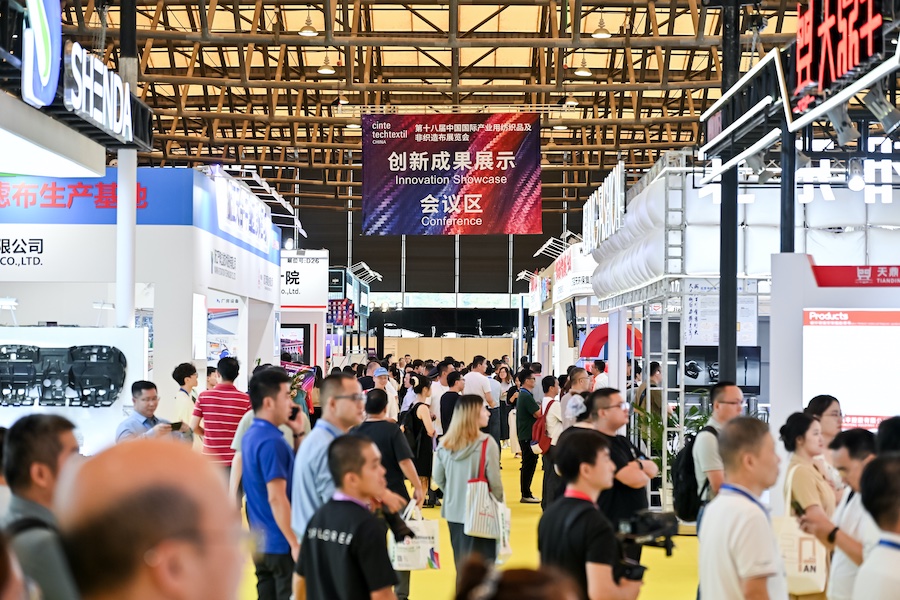

The fair attracted nearly 20,000 visits from 74 countries and regions – a 17% increase from last year, and, as the most comprehensive edition ever in terms of product categories, visitors had much to explore. Major fringe events, such as the China International Nonwovens Conference (CINC), Econogy Tour[1], Sustainability Forum, and AI Panel, effectively linked innovation and sustainability with industry demands, maximising reach and business opportunities for participants.

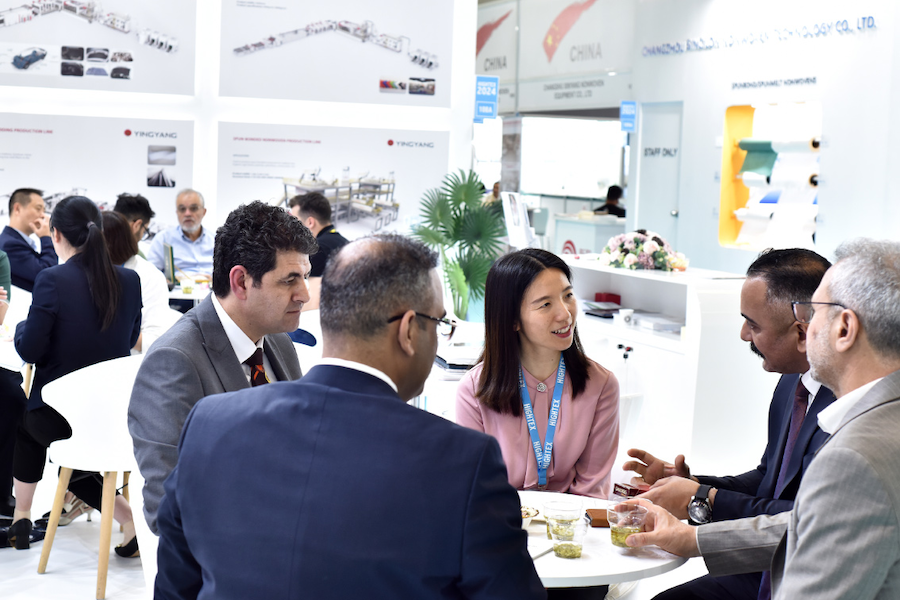

Ms Wilmet Shea, General Manager of Messe Frankfurt (HK) Ltd, was delighted to see engaging dialogues taking place onsite: “Cinte Techtextil China boasts a unique positioning, featuring highly functional, specialised and sophisticated products and technologies. Upholding the brand’s reputation for the cutting-edge, we continuously seek to integrate innovation and sustainability with new avenues for growth. This year's new product categories and enhanced fringe programme infused fresh energy and opportunities, making the show a launchpad for exploring new domestic and international market potential. Chance encounters are a key driver in business, and we’re proud to have facilitated many of these at this show – which achieved solid results and instilled confidence in the industry’s future.”

As Asia’s only dedicated show for the full spectrum of technical textiles and nonwovens, Cinte Techtextil China 2025 hosted over 300 global exhibitors, and welcomed a wide range of visitors, including sourcing decision-makers, textile & mechanical engineers, product developers, researchers, and more. The fair saw a significant rise in visitor pre-registrations, with international numbers increasing by over 40% compared to the previous edition. VIP buyers from across the globe attended the fair, as did 14 visitor delegations with over 250 participants. Some of the leading brands included domestic representatives from Kimberly-Clark (China), Li Auto, Li Ning, and L'Oréal (China); and international participants from Lego System (Denmark), Norafin Industries (Germany), Rockline Industries (USA), and Toyoshima & Co. Ltd (Japan). Strong visitor engagement opened new prospects for new and returning exhibitors across Halls W3 to W5.

Among the returning exhibitors, key international players included AUTEFA Solutions, Lindauer DORNIER and Rowa Group from Germany, Fil Man Made Group from Italy, Graf + Cie and Swisstulle from Switzerland, Picanol from Belgium, and more. This edition also welcomed several newcomers, partly due to the incorporation of textile chemicals and dyes into this year's product categories. Key exhibitors making their debuts included: Serel Industrie (Belgium) and Proton Products (UK) in the European Zone; Wetekam Group in the German Zone; Dupre Minerals (UK) and Michelman (USA) in the Textile Chemicals and Dyes Zone; Huamao (Xiamen), BW Advanced Materials, Shanghai Shenda, and Zhejiang Kingsafe Group from China, JCT Industries Group from Malaysia, Vietnam Geotextile from Vietnam, and more.

To support the diverse array of exhibitors and visitors onsite, Cinte Techtextil China identified specific development areas and offered relevant fringe events to facilitate meaningful interaction. The Econogy Tour and Sustainability Forum promoted the industry’s eco-transition, with the latter sparking cross-sector discussions among academia, brands, and other industry players. On the innovation front, the AI Panel and the Innovation Product Award and Presentation provided forward-looking insights from various perspectives, helping the industry reshape its future.

Other events like the CINC, themed ‘Breaking the Deadlock and Reconstruction’, offered in-depth discussions and report presentations for the nonwovens industry to navigate upcoming challenges and opportunities. To harness the promising Mobiltech trend, the fair organised a Technical Innovation Exchange Conference on Automotive Textiles followed by a tour visiting related exhibitors. Interested parties could also enjoy live-streamed tours organised for in-demand sectors such as Medtech, Mobiltech, and Protech.

First-time exhibitors found business value at Cinte Techtextil China

First-time exhibitors also confirmed the strong business value of Cinte Techtextil China. “We received over 80 enquiries in just two days, which is excellent for our debut at the fair,” reported Reece Berrisford, Sales Manager at Dupre Minerals (UK). He highlighted the high interest from Chinese buyers, particularly in filtration and air conditioning fabrics, and noted: “China’s demand for innovative solutions is strong, especially in fire protection.”

From Vietnam, Nhu Quynh Nguyen of Vietnam Geotextile Joint Stock Company emphasized the international scope of the fair: “Cinte Techtextil China effectively met our core objectives of showcasing innovations and initiating new business relationships. It is well suited to expand reach and crucial for market entry into China.”

Hiyen Lin, Regional Manager at HUAMAO (Xiamen) Special Material Co Ltd, China, underlined the fair’s role as a springboard for exports: “This influential fair is vital for expanding our overseas customer base. We connected with numerous international buyers from Europe, our target group, and found the event highly effective in facilitating high-quality meetings.”

Buyers also praised the comprehensive offerings.

For Harald Bartisch, CEO of Blue Brain Alpha Science Coaching/Consulting (Austria), the fair opened up entirely new sourcing opportunities: “The fair’s internationality allowed me to discover unique materials and techniques from around the world. It is a sizable, effective platform – easy to meet people face-to-face and to see the products.”

Williams Peeters, Sourcing Manager at Milliken Textiles BV (Belgium), pointed to the importance of sustainable alternatives: “With sustainable yarns increasingly important in Europe but limited there, I find the Asian and Chinese markets effectively filling these gaps. I was pleasantly surprised by the nonwoven materials available onsite.”

From China, Bintao Chen, Marketing Director at Zhejiang Aiye Lvbu Co Ltd, praised both scope and efficiency: “The benefits and the international level exceeded expectations. My sourcing efficiency improved significantly, and I was particularly impressed by new fibreglass filter materials.”

Conference speakers equally valued the platform for dialogue

Karl Borgschulze, Managing Director of Consulting Service International Ltd (Hong Kong), stressed the visibility that sustainability-focused companies gained through the Econogy Tour: “The Econogy symbol served as an excellent promotional tool, highlighting exhibitors to international buyers and journalists – a powerful opportunity to promote their concepts globally.”

Prof. Calvin Wong, CEO of the Laboratory for Artificial Intelligence in Design (AiDLab) at Hong Kong Polytechnic University, emphasized the practical impact of the AI Panel: “It clarified AI concepts in fabric inspection while highlighting innovations in our technology. By participating, we gained direct insights from potential clients, allowing us to adjust our technology to market demands.”