#Research & Development

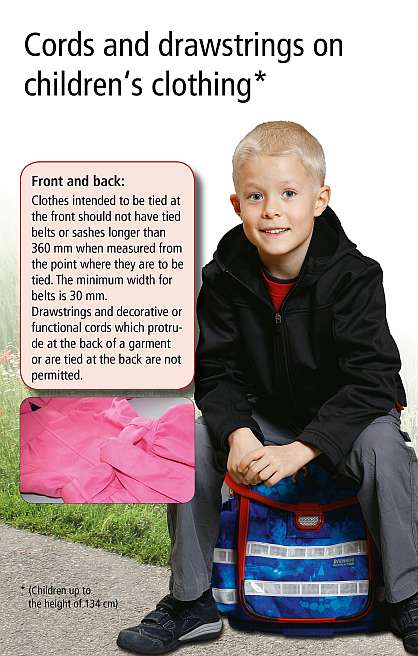

Keep away from cords and drawstrings!

It is frightening how many recall campaigns are listed on the information page of the European Union(1) for products presenting a risk of strangulation or serious injury. In the past fatalities and major injuries have unfortunately occurred time and time again due to the use of unsuitable closures on children's clothing. A fact that is barely recognised in the public debate surrounding the safety of textiles. Instead, the focus falls here on possible contamination with harmful substances.

Christiane Schulze from the Hohenstein Institute in Bönnigheim is pressing for even greater caution in the interest of children: "Most textiles on the market are now tested for harmful substances, as for example under OEKO-TEX® Standard 100. And there has been a significant fall in the number of complaints involving this aspect. I am hoping to see a similar positive trend where the Cord Regulations are concerned."

Christiane Schulze's team of staff are also making a contribution here, working on behalf of manufacturers and trading companies: They examine clothing designed for children and adolescents in relation to the DIN EN 14682 safety norm before manufacturing starts, so avoiding product recalls from the outset.

(1)

http://ec.europa.eu/consumers/safety/rapex/alerts