#Research & Development

ITMF International cooperation award 2024 goes to the DITF and RBX Créations

New fibers and textile products from hemp - with the presentation of an innovative production line, the cooperation partners DITF and RBX Créations are focusing on the concept of sustainability in the textile value chain. The raw material hemp is obtained from local cultivation, and further processing into textile fibers, yarns and fabrics made of cellulose is carried out using energy- and resource-saving processes.

With this in mind, the two partners successfully presented themselves at the ITMF & IAF Conference 2024 in Samarkand, Uzbekistan. Together, they presented a complete textile production chain to the audience and the jury - from raw materials to processing, spinning technology and the realization of textile products.

Even the choice of hemp as a raw material is beneficial to the environment in many ways: it is grown locally and therefore has a low carbon footprint: This is because wood is usually used as a raw material for the production of cellulose fibers, and long transportation routes are accepted for its processing. The cultivation of hemp is characterized by low water consumption, little or no use of chemicals due to high resistance to plant diseases, and beneficial properties for soil regeneration.

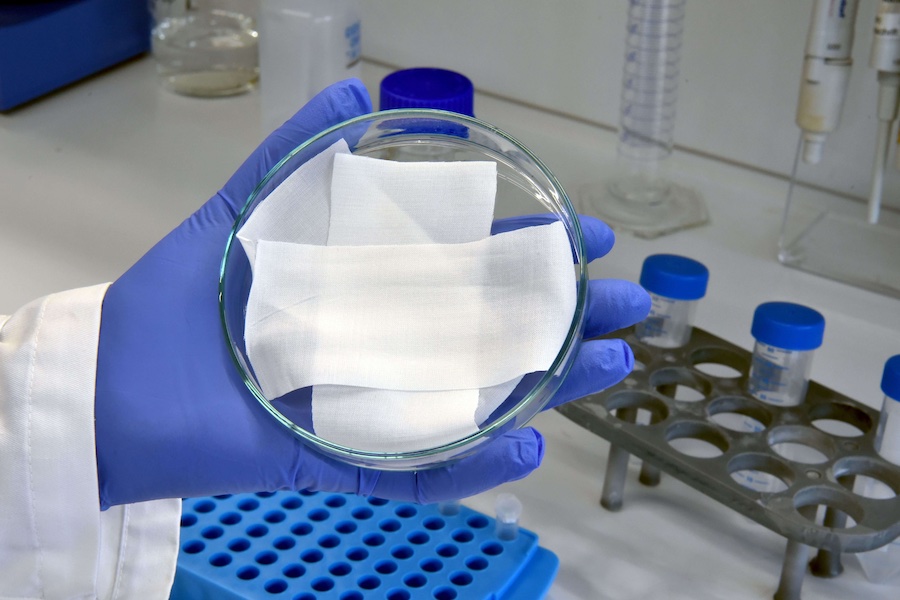

Industrial hemp is processed into a fine-fibred pulp in a process patented by RBX Créations. It serves as the raw material for a wet spinning process developed at the DITF and patented under the name HighPerCell®. The hemp pulp is dissolved in an ionic liquid. The solution is spun into cellulose fibers in a precipitation bath. The solvent can be completely recovered and reused - a highly sustainable and environmentally friendly production process. Hemp-based cellulose fibers have impressive mechanical properties, some of which are even better than those of established wood-based fibers. This makes them ideal for mechanical processing in knitting and weaving.

The project partner RBX Création has not only developed the processes for the preparation of the raw materials, but also manages the further processing of the fibers after production: thanks to its excellent network in the textile industry, RBX Création is responsible for the preparation of the yarns and coordinates the distribution of tasks with the textile manufacturing companies. The yarns and textile materials are marketed by RBX Création under the name Iroony™. Knitted and woven fabrics have already been produced from this material. Whether for clothing or technical applications, hemp-based materials have a wide range of uses and great development potential.

The award ceremony in Samarkand recognizes the entire manufacturing process: a new and sustainable process for the production of natural fibers is controlled in a company and research cooperation from the cultivation of the raw material to the final product. The collaboration shows how sustainability in textile production can lead to new and marketable products.