#Research & Development

No sustainable future without carbon capture and utilisation (CCU) – Why we need much more political recognition and support for CCU

The Renewable Carbon Initiative (RCI), an alliance of more than 60 well-known companies, SMEs and start-ups, commissioned the German nova-Institute to write the unique background report entitled “Making a Case for Carbon Capture and Utilisation (CCU) – it is much more than just a carbon removal technology”. The report is a science-based appeal for CO2 utilisation.

The central goal of the RCI is to facilitate the transition from fossil to renewable carbon in all chemicals and materials. Besides biomass and recycling, carbon capture and utilisation (CCU) is one of the three available options to provide renewable carbon, but its potential is not yet fully recognised by policy makers. One main cause is the widespread misconception that CCU only delays emissions and therefore does not contribute to climate change mitigation or net-zero targets – two critical goals that are at the heart of global climate policy. When policy accepts CCU, it is often in the context of long-term storage of carbon or atmospheric/biogenic carbon dioxide removal.

CCU is much more than a carbon removal technology

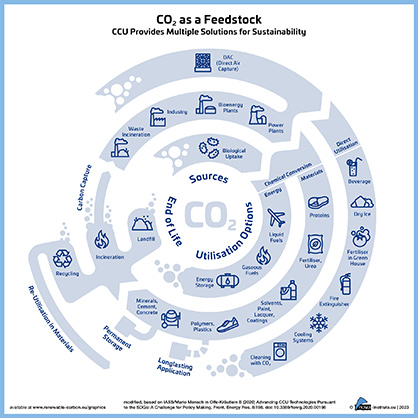

The latest paper of the RCI makes a clear case in favour of CCU: the technology offers multiple solutions to pressing problems of our modern world and can support several Sustainable Development Goals if implemented properly. In total, 14 different benefits and advantages of CCU are described and discussed in the paper. A key advantage is that CCU supplies renewable carbon to – and thereby substitutes fossil carbon in – sectors that will require carbon in the long run. This includes the chemical sectors and products like polymers, plastics, solvents, paints, detergents, cosmetics or pharmaceuticals. Several CO2-based plastics, detergents, textiles, or fuels are already in production and on the market (figure 1). But CCU is also essential to a long-term net-zero strategy, crucial for creating a sustainable circular economy, providing solutions for scaling up the renewable energy system, and bringing multiple benefits for innovation and business. The relevance of the technology is not yet accepted in Europe, but the RCI wants to make a very clear statement:

CCU is a central pillar for the biggest transformation of the chemical and material industry since the industrial revolution

– to decouple the petrochemical industry from fossil carbon, by using renewable carbon. CCU is a crucial technology for the future, as it enables the substitution of fossil carbon in sectors where carbon will be needed long-term and supports the full defossilisation of the chemical and derived material industries. CO2 can be captured from various sources and converted into a wide range of fuels, chemicals and materials (figure 2). Without CCU, only recycling and biomass remain to supply the entire non-fossil carbon demand of a sustainable, defossilised future. But all three options combined maximise the technological potential to find best solutions for any given situation and allow the creation of a circular carbon economy. By creating sustainable carbon cycles, CCU reduces the emission gap and promotes the circular economy. Moreover, CCU fosters innovation, generates local value, and stimulates job growth. The consequence of not embracing CCU will be prolonged dependence on fossil feedstock.

Christopher vom Berg, one of the main authors of the paper: “Every gram of carbon that can be kept in the cycle through CCU does not have to be extracted (from fossil resources) or injected into the ground through CCS1. CCU is the epitome of a circular (carbon) economy!”

Why is there only limited adoption of CCU as of yet?

CCU is a young and energy-intensive industry with only a few clear advocates. The technology competes with well-established, upscaled industries that have powerful lobbies (e.g. fossil industries, biofuels sector), across multiple products and sectors. And the strong net-zero focus in policy leads some stakeholders to disregard the remaining future demand for carbon as a feedstock – and therefore to push only for zero-carbon energy and carbon storage of remaining emissions.

Harmonised regulatory support is lacking when it comes to CCU. Instead, a patchwork of regulatory incentives and barriers are in place. This patchwork currently encourages CCU for fuels and for long-term storage, but not for the only sector that has a clear long-term need for carbon supply – chemicals and materials. At the same time, CCU as a recent technology lacks clear advocacy and struggles to gain a foothold under competition to strong, long-established sectors. In order to support the development of the entire carbon capture sector and to enable the development of CCU into a central pillar of comprehensive carbon management, proper endorsement and support by policy will be necessary.

It is RCI’s belief that Europe’s first priority should be to minimise the emission gap (and thus the problem of overshooting carbon emissions) as much as possible, while developing carbon dioxide removals as the technological back-up plan to achieve our climate targets. Failing on these targets is simply not an option and therefore well-established carbon capture technologies need to be developed and scaled. But with strong investment in renewable energies and CCU, the remaining emission gap can be significantly reduced to only the truly unavoidable emissions.

Michael Carus, one of the main authors of the paper: “It is simply absurd that power stations and industry should store their CO2 emissions in the ground at great expense via long pipelines (CCS), while at the same time continuing to use fossil carbon from the ground – instead of driving the carbon around in circles via CCU. It is a political scandal not to create a policy framework in Europe that stimulates the capture and use of ongoing fossil CO2 emissions.”

The background report identifies and discusses 14 significant benefits and advantages that CCU can deliver and promotes twelve policies measures to fully realise these benefits.

The entire report is available at:

https://renewable-carbon.eu/publications/product/making-a-case-for-carbon-capture-and-utilisation-ccu-it-is-much-more-than-just-a-carbon-removal-technology/

1) CCS means Carbon Capture and Storage