#Research & Development

Cheaper Formula 1 cars

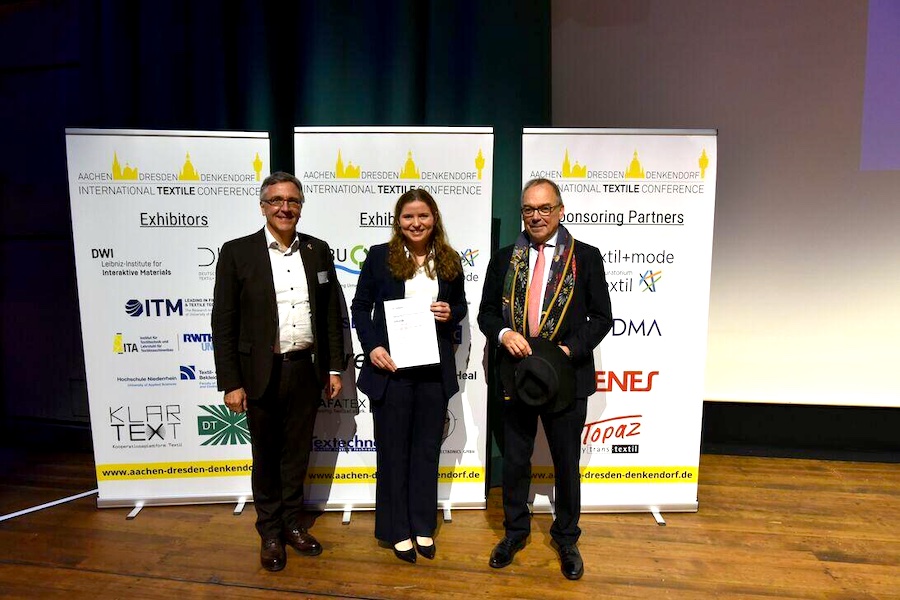

For this idea, the young engineer Deniz Sinan Yesilyurt received the second prize of the "Digitalisation in Mechanical Engineering" Young Talent Award on 6 December.

Carbon fibres are sought after because of their good mechanical properties. They are very light - weighing up to 50 percent less than aluminium by the same strength. This offers many advantages. Especially in times of energy transition, lightweight materials like carbon are more relevant than ever. At the same time, carbon fibres are as resistant to external stresses as metals. However, achieving these good properties of carbon fibres is very complex.

Up to 300 individual fibre strands - bundles of individual fibres - have to be monitored simultaneously during production. If carbon fibres break, it costs time and money to remove the damaged fibres. This is just one example of various defects that can occur in the fibres during production.

Therefore, Mr Yesilyurt attached a camera to the carbon fibre line that takes pictures of various fibre defects during production and collects them in a database. The artificial intelligence in the camera's information technology system evaluates the fibre defects by assigning the images to predefined reference defects. Hence, it recognises various fibre defects with a classification accuracy of 99 per cent. The process developed by Mr Yesilyurt can also be used in other areas that produce chemical fibres.

Deniz Sinan Yesilyurt received the prize from the German Engineering Federation (VDMA) in Frankfurt am Main, Germany. He is a Bachelor's graduate at the Institut für Textiltechnik (ITA) of RWTH Aachen University. The full title of his bachelor's thesis is: "Development of a Kl-supported process monitoring using machine learning to detect fibre damage in the stabilisation process". The VDMA awarded the prize to a total of four theses from different universities from Germany, Austria and Switzerland.