#Recycling / Circular Economy

Toray to domestically sell chemical recycled fiber products derived from fishing nets

Toray looks for N6CR product sales to rise from around 800 million yen in the year ending March 31, 2023, to 1.2 billion yen two years later.

This year, Toray set up a new production system at its Nagoya Plant that identifies virgin raw materials from fossil sources. This setup comprises a raw materials input facility for recycled fishing net-derived resin and recycled lactam storage tanks. This setup will recycle nylon 6 fiber products, accelerate efforts to develop an advanced fiber to fiber recycling business, and contributing to a circular economy.

Toray’s new N6CR facility will enable it to overcome technical challenges and reinforce its range of high-performance, high-value-added nylon fibers for apparel. The company looks particularly to expand sales of thin, eco-friendly fabrics for sports and outdoor wear, innerwear, and legwear.

Common applications for industrial nylon fiber are automotive parts, ropes, fishing nets, carpets, and other general industrial materials. Toray’s endeavor will help cut environmental impacts across an array of industrial fields and drive uptakes of sustainable resources.

Toray will expand its advanced fiber to fiber recycling business by collaborating with customers in initiatives to sell products incorporating its N6CR materials. Such endeavors will be in keeping with the company’s commitment to innovating ideas, technologies, and products that deliver new value.

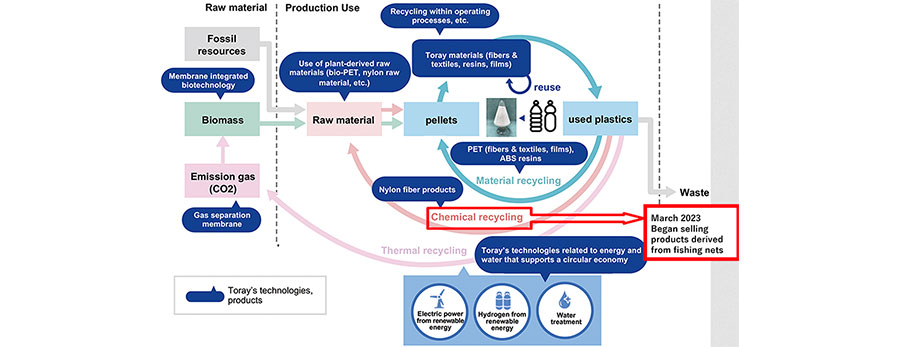

One goal of the Toray Group Sustainability Vision is to help the world manage resources sustainably by 2050. Toray will accordingly keep pursuing that vision to help eliminate resource depletion and marine pollution from large amounts of waste, cut carbon dioxide emissions, and tackle other issues to materialize a circular economy.

1. Overview

(1)? Planned sales launch: March 2023

(2)? Annual production: Around 400 metric tons

(3)? +Sales target: 800 million yen in year ending March 31, 2023, rising to 1.2 billion yen in year ending March 31, 2025

2. Toray Group circular economy initiatives

Reference

Refineverse Group website

https://r-inverse.com/