#Recycling / Circular Economy

Swiss ecosystem makes textile fibers circular

The Swiss Textile Recycling Ecosystem has been launched. It brings together key players from across the entire textile value chain to create a circular economy. An innovative recycling technology from Worn Again Technologies (WAT) is at the heart of this. Based in the UK, WAT announced at the start of June that it plans to build a demonstration plant near to its technology and scale-up partner Sulzer Chemtech in Winterthur in the canton of Zurich. WAT was also the source of inspiration for this consortium.

The partners will provide WAT’s demonstration facility with various types of textile waste. According to a press release, this can process 1,000 metric tons per year. After processing, industry players will be supplied with innovative recycled fibers made from PET and cellulose to create new, high-quality textiles.

The consortium’s shareholders are WAT, Sulzer, Oerlikon from Freienbach in the canton of Schwyz, and the H&M Group. Rieter, a spinning machine provider with headquarters in Winterthur, will support cellulose spinning. Monosuisse from Emmenbrücke in the canton of Lucerne, a manufacturer of synthetic monofilaments for industrial applications, will take on PET fiber production. The Swiss retail and wholesale company Coop headquartered in Basel will act as a collector and raw material supplier. Texaid, which reuses old textiles, will supply the starting materials together with ISA Sallmann from Amriswil in the canton of Thurgau and Serge Ferrari, a French technical textile manufacturer above all active in the construction industry. All of this is being organized by the textile umbrella organization Swiss Textiles from Zurich.

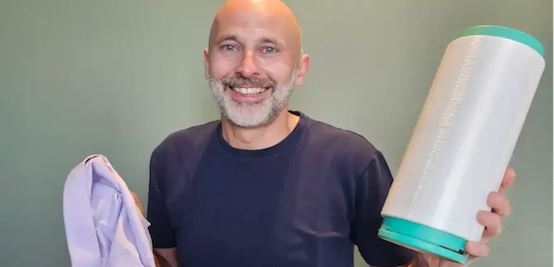

Torsten Wintergerste, Chairman of WAT and Division President at Sulzer Chemtech, commented: “The collaboration will also play a vital role in developing our capacities and building up a network to support the construction of large-scale plants across the world.”