#Raw Materials

New meta-study highlights that hydrolysis prevents the formation of persistent PLA microplastics in the environment

A new meta-study report commissioned by Holland Bioplastics, an association advancing bioplastics knowledge worldwide, concludes that the fundamental characteristics of polylactic acid (PLA), a biobased polymer made entirely from fermented plant sugars, and the hydrolysis process indicate that PLA does not produce persistent microplastics. The literature research, completed by HYDRA Marine Sciences, a research laboratory, shows that unlike non-biodegradable polymers, which will persist and permanently accumulate as nano- or microplastics in the environment, PLA will hydrolyze into molecules of ever-smaller size, becoming soluble in water and eventually fully biodegraded.

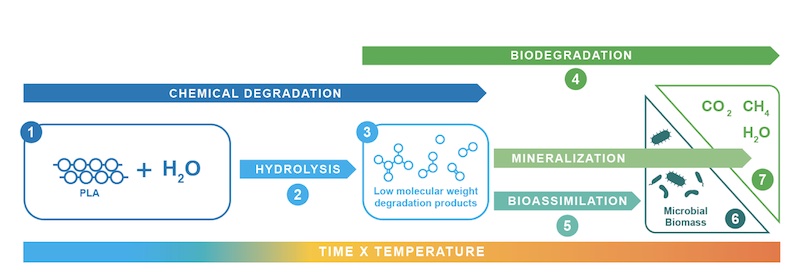

The report’s findings were drawn from an initial scan of over 30,000 reports, of which 500 were identified by HYDRA as relevant and of sufficient quality for deeper review. The research confirmed that the environmental degradation of PLA is mainly driven by hydrolysis, an abiotic process that occurs in the presence of moisture or humidity. As long as these conditions prevail, the molecular weight and size of any PLA objects or fragments will continually decrease via hydrolysis, at a rate determined by temperature, until the polymer chains are so short that the material becomes soluble in water. These soluble substances, oligomers and lactic acid monomers, will subsequently be biodegraded by microorganisms into biomass, water, and carbon dioxide.

Neat PLA and its oligomers are also widely recognized as non-toxic substances. Lactic acid, the monomer building block of PLA, is classified as Generally Recognized as Safe by the US Food and Drug Administration and European Union (EU). Many PLA grades comply with long-standing global legislation for food contact requirements in the US and EU. Additionally, specific grades of PLA have been approved and used for decades in medical applications such as sutures, tissue scaffolds, and drug administration substrates. After use in the body, these PLA polymers are safely absorbed and bioassimilated by the human body.

“As a society, we must work to end the plastics crisis from both ends: developing collection and waste processing infrastructure and products that are compostable, reusable, and recyclable while simultaneously choosing more responsible materials for the products we rely on today,” said Erwin Vink, Board Member from Holland Bioplastics. “These findings confirm that as we are growing access to waste infrastructure globally if PLA is leaked into the environment, it will not have the long- term impact as a microplastic that we know occurs with non-biodegradable polymers.”

“The meta-study shows that in contrast to non-biodegradable plastic, which will persist and permanently accumulate as micro- and nanoplastics in the environment, PLA in the environment will not leave persistent pollution as long as humidity and water are present,” said Christian Lott, Managing Director, HYDRA Marine Sciences. “However, we must be aware that it does not belong in the environment, and it is critical that we do not use these attributes to encourage littering or slow the development of global waste infrastructure. Degradation of any material must be balanced with accumulation, or how much material is entering the environment, in order to reduce harm to the environment.”

Producing the biobased polymer, PLA, starts with plants as they sequester atmospheric carbon dioxide in sugar molecules through the process of photosynthesis. Plant sugars are then fermented using microorganisms to produce the monomer lactic acid, a safe, non-toxic substance that is also used to preserve foods and is produced by our bodies during physical exertion. This lactic acid is then polymerized into the polylactide (PLA) biopolymer used to make a wide range of products like cups, cutlery, bin liners, or flexible food packaging. Because PLA is made from plants that absorb carbon dioxide (CO2) and water found in nature, when it is composted, hydrolyzed, or biodegraded, the CO2 and water will return back to nature, making the process circular.

To follow Holland Bioplastics and its member companies that supported this study, Futerro, Total- Energies Corbion, and NatureWorks, as they continue to make strides toward the global expansion of bioplastics for a circular economy, visit hollandbioplastics.nl.